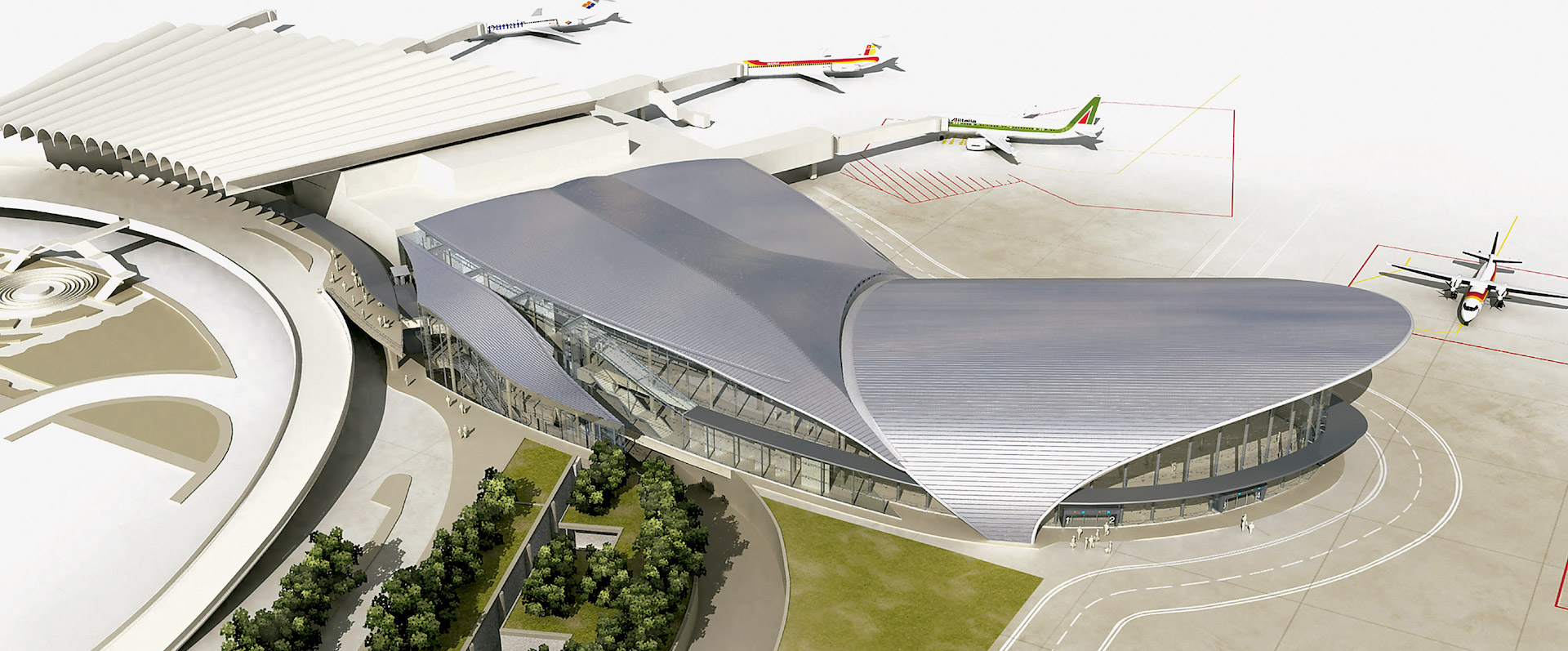

Project Requirements

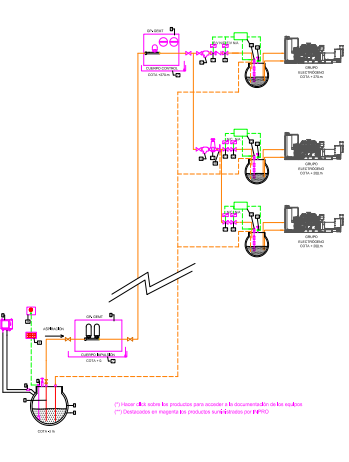

The following project was an immense challenge, not only because of the height of the systems but also due to the requirements of the project regarding fire protection and fuel spillage in such a singular building: a unique installation.

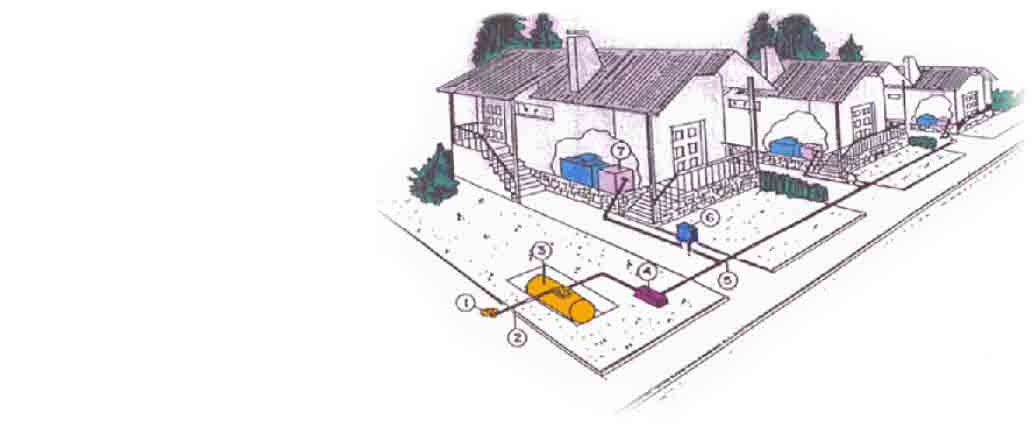

Inpro Solution

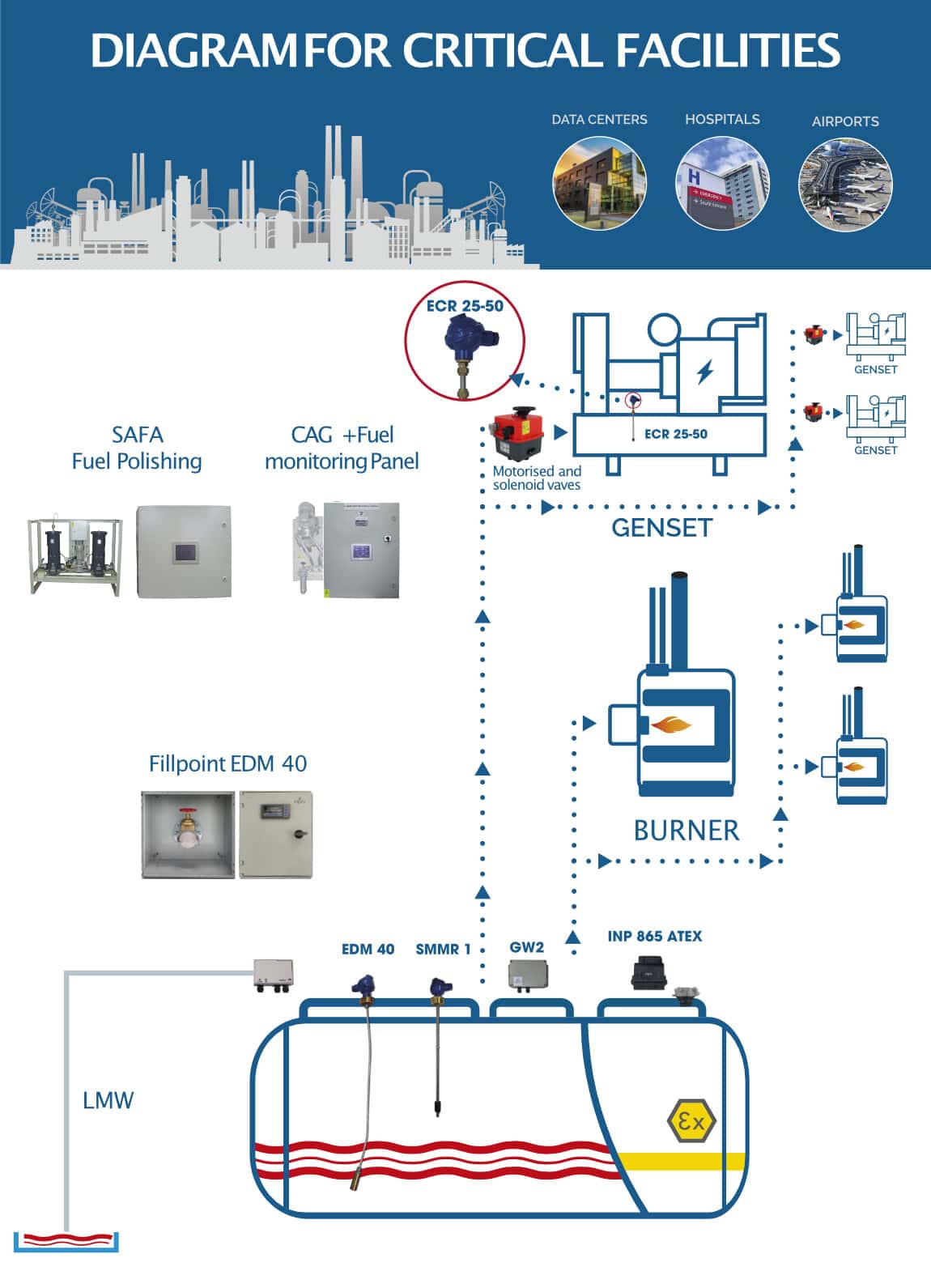

It required automation and control of the gas oil supply needs from the main tank to the daily service tanks in all three power generators located at different altitudes. One on the roof, 270 m high, and the other two at 198 m from the propulsion unit of the pressure unit.

Pipes were selected according to the criteria of standard DIN 4755. To detect leaks in the double skin of the main tank, we chose a DDP-25 vacuum system with regenerative pump and fluid separation valve.A digital level display is installed, with EDM-40 continuous analog probe for local reading of the capacity of the tanks and analog outputs (0-10V – 4/20 mA) .

Equipment

-

Probe EDM40

-

Interstitial chamber detector DDP-25

-

Collector tray with spillage detector

-

Solenoid valves

-

Pressure reducing valve

-

Level switch – SMMR

-

Pressure unit GP-GEMT

If you belong to the engineering, construction or project consultancy sector and you are interested in learning more about this project and many others, you can download the PROJECT BOOK