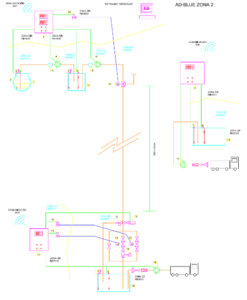

PROJECT REQUIREMENTS:

The main difficulties were to overcome height difference about 600m from the daily surface tanks to the main tanks installed inside the mine; and achieve ATEX certification.

Solution adopted by INPRO

Carefully select and separate in design phase the devices that are installed in the Risk-area and Non-Risk-area (ATEX certification)

EQUIPMENT

- Tank control: EDM-40 ATEX

- Level switches SMMR-2 explosion-proof head

- Pumps explosion-proof: 1 x fuel pump (80L/min)

- 1 x fuel pump (200L/min)

- Solenoid valves

- PLC control system

- Pressure regulator