Project Requirements:

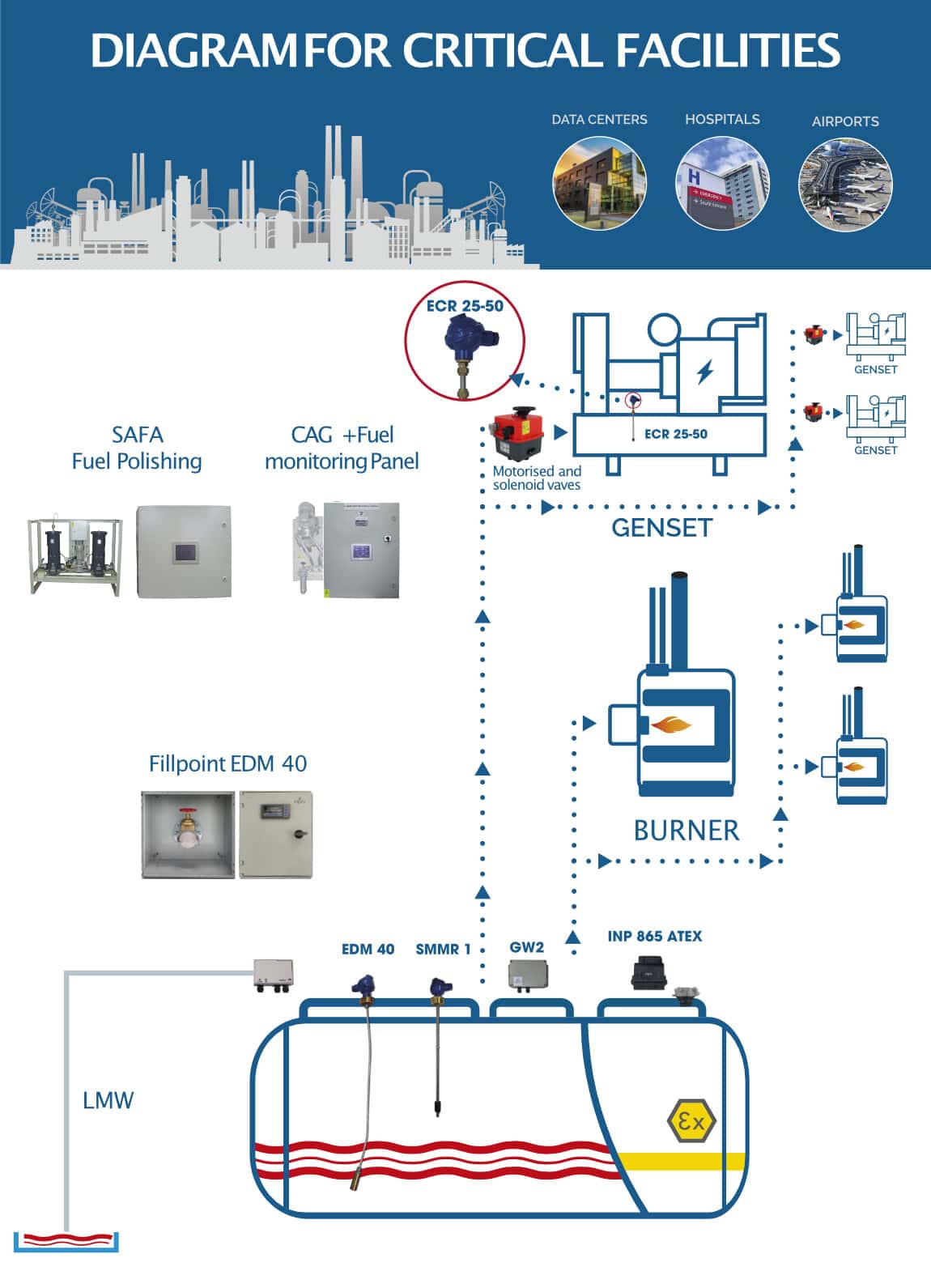

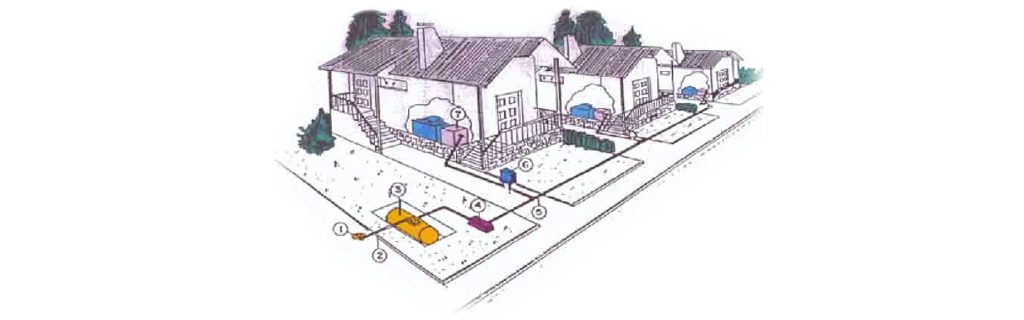

The customer requested a TIER IV redundant fuel supply to gensets, with automatic protocols for:

– Storage tanks filling

– Storage Tank suction protocol and refill of Day Tanks

– Leak detection at Storage tank + several leak detection points

Metro (underground) de Madrid started the construction of this Global Data Processing Centre (DPC), which will house and consolidate the company’s technological infrastructures used to manage operations, tele-maintenance and company information.

Inpro Solution:

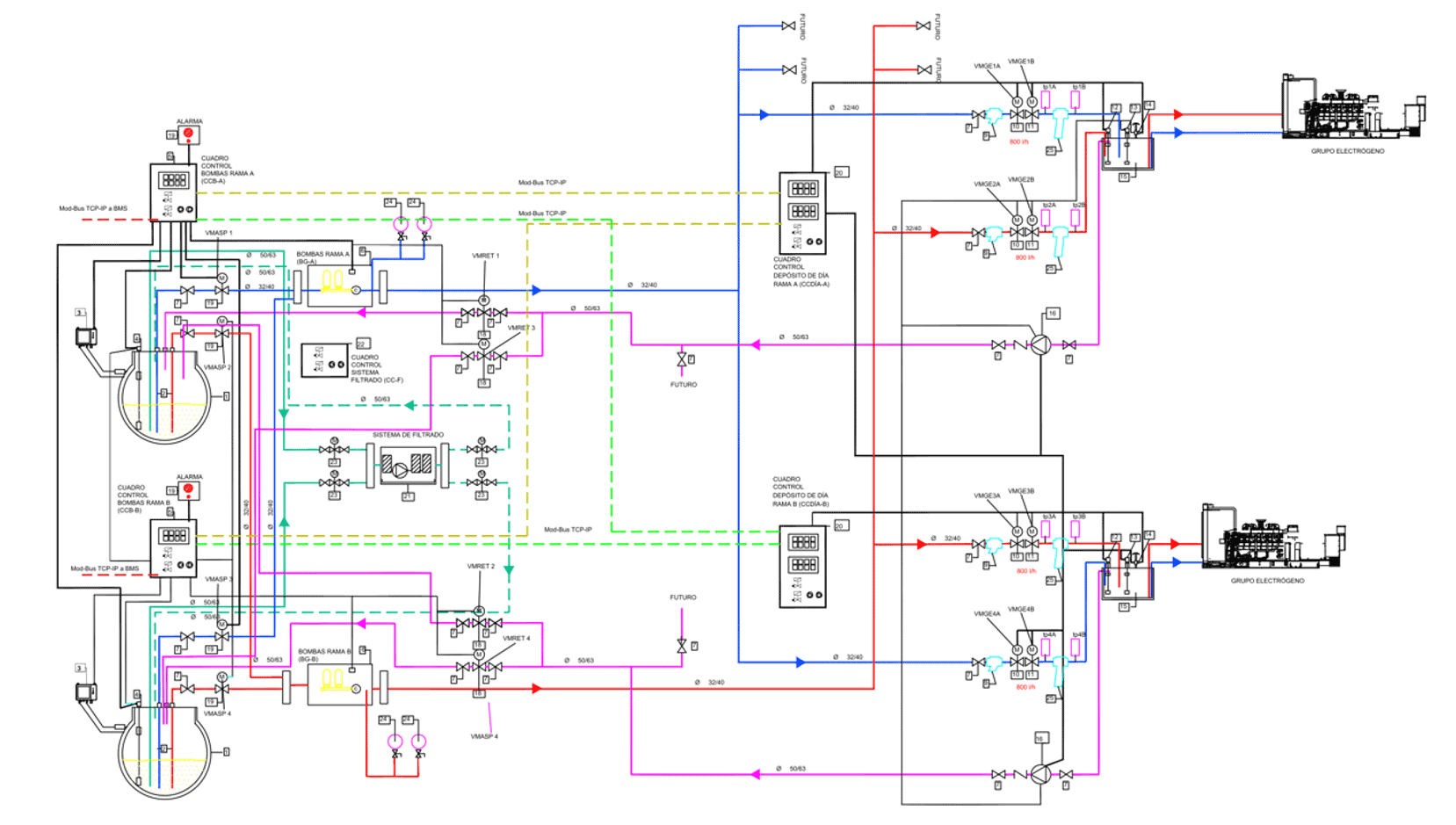

The complete installation consists of two different fuel supply systems for the gensets, controlled by a PLC. The whole installation has two main storage tanks, 2 PLC based fuel monitoring panels, controlling 2 +ATAM-3200 GET duplex pumps and al the fuel instrumentation

The genset ring pipeline suck fuel from these two main tanks. The installation is delivering fuel to 4x gensets through their corresponding day tanks, through 2 master CAG panels controlling also the safety devices and their return single pump units.

A SAFA fuel polishing systems are guaranteeing the diesel availability without water, bacteria or yeasts.

Equipment:

-

Main tank control: EDM-40 probe with display

-

Leaks detection: DDP-25 interstitial chamber detector

-

LMW Leak detector – Wall mounting version

-

2 x fuel pump FP ATAM-3200 GET

-

1 x fuel polishing system SAFA

-

Solenoid valves: control the filling process

-

PLC control system

-

Collector tray with leak detector

-

Pressure and Level switches SMMR

-

Flow meter and Pressure reducing valve