PROJECT REQUIREMENTS:

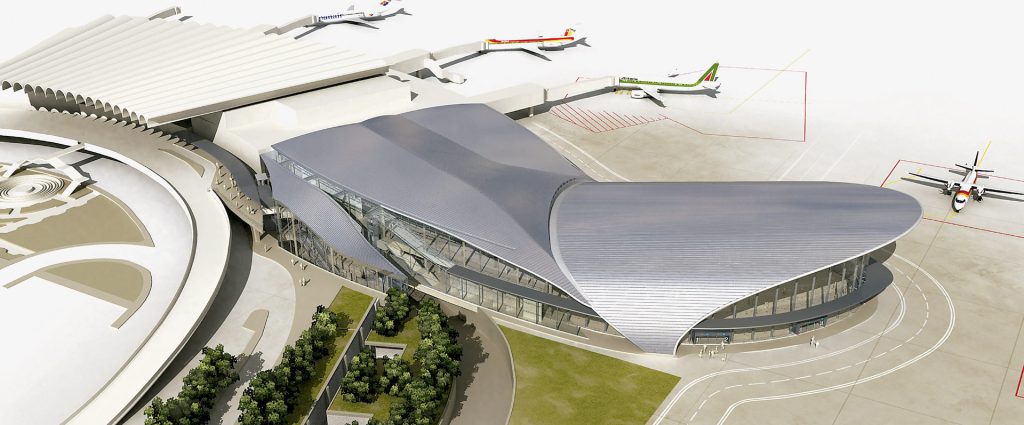

The customer requested gas oil pumping to the daily service tanks of the emergency or normal operation power generator units.

Solution adopted by INPRO

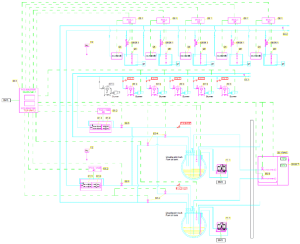

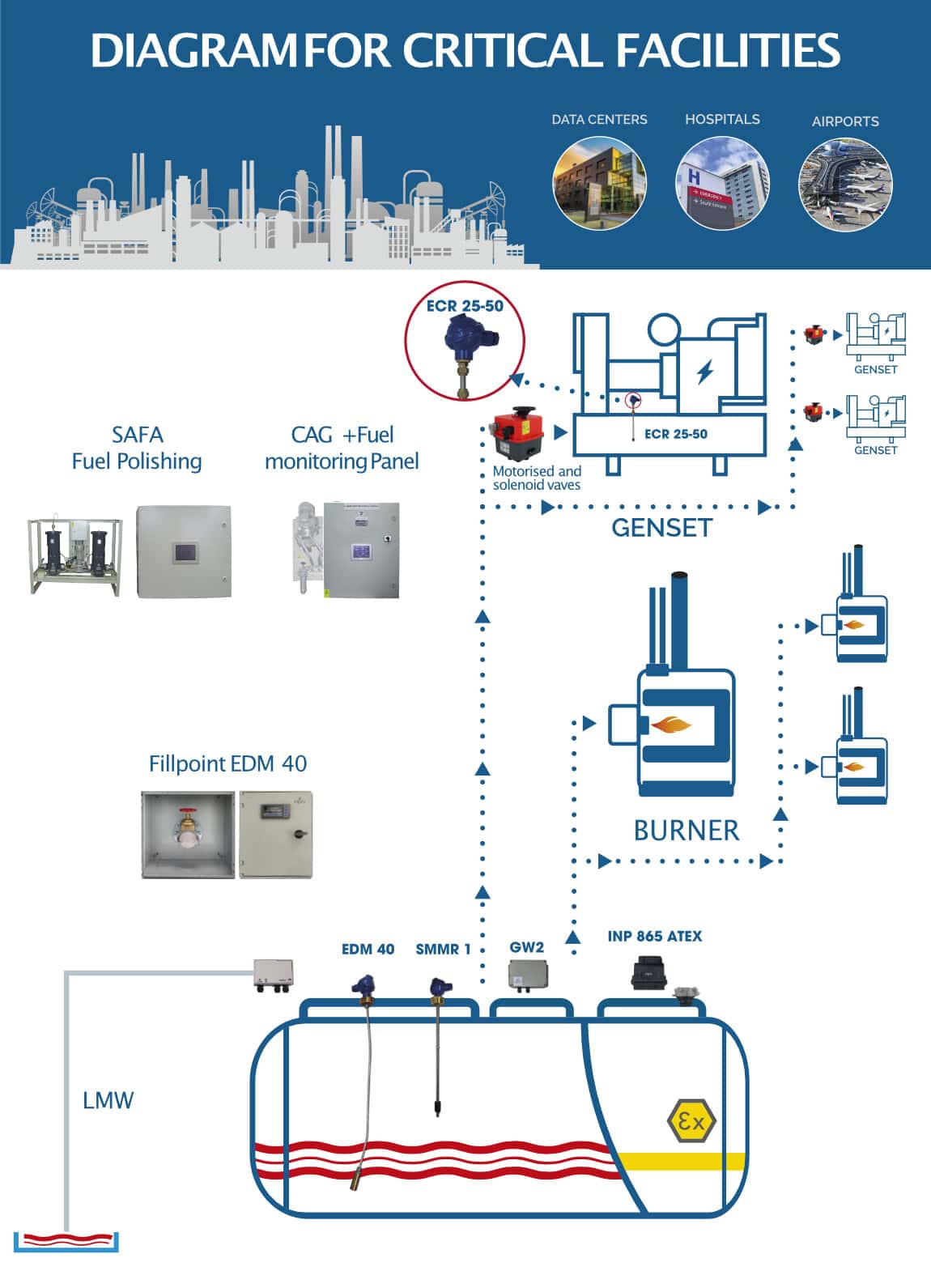

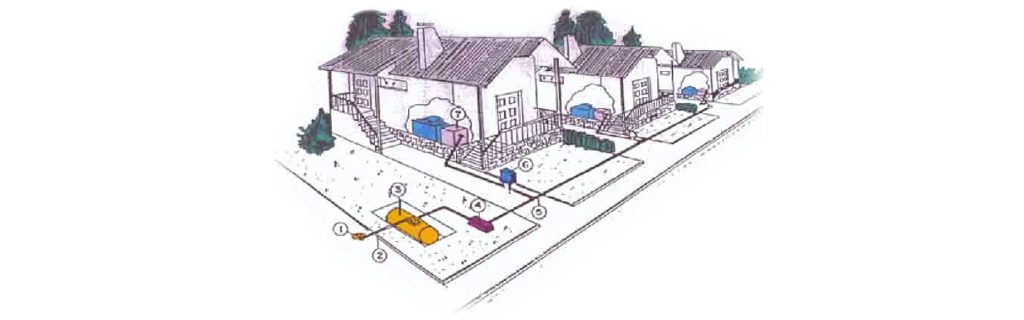

The complete installation consists of two different fuel supply systems for the burners and gensets, both controlled by a master PLC . The whole installation has two main storage tanks. Both the burner ring pipeline and the genset ring pipeline suck fuel from these two main storages. The burner’s supply installation is composed of a double pump unit, and five burners with the corresponding inlet stabilizer. The genset’s supply installation is composed of a double pump unit and five electric generators with their corresponding daily tanks with the safety devices and their return single pump units.

The master PLC control will be redundant with two separate PLC programmed to control all the installation. There will be two different communication lines for each PLC, one via Modbus and the other via TCP-IP as well: there will be 4 redundancy communication control channels.

EQUIPMENT

- Main tank control: EDM-40 probe

- Leaks detection: DDP-25 interstitial chamber detector

- Pump system: 2 x duplex fuel pumps RL 7 (5300 L/h)

- 5 x simplex fuel pump FP 90 (900 L/h)

- 2 x fuel polishing systems SAFA

- Solenoid valves: to control the filling process

- Pumpset control cabinets: Inpro CAG+

- Collector tray with leak detector

- Level switch: SMMR