ALGIERS AIRPORT

Filling Automation of tanks to supply the demand of the diesel back up generator

PROJECT REQUIREMENT:

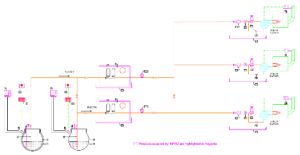

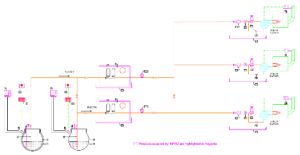

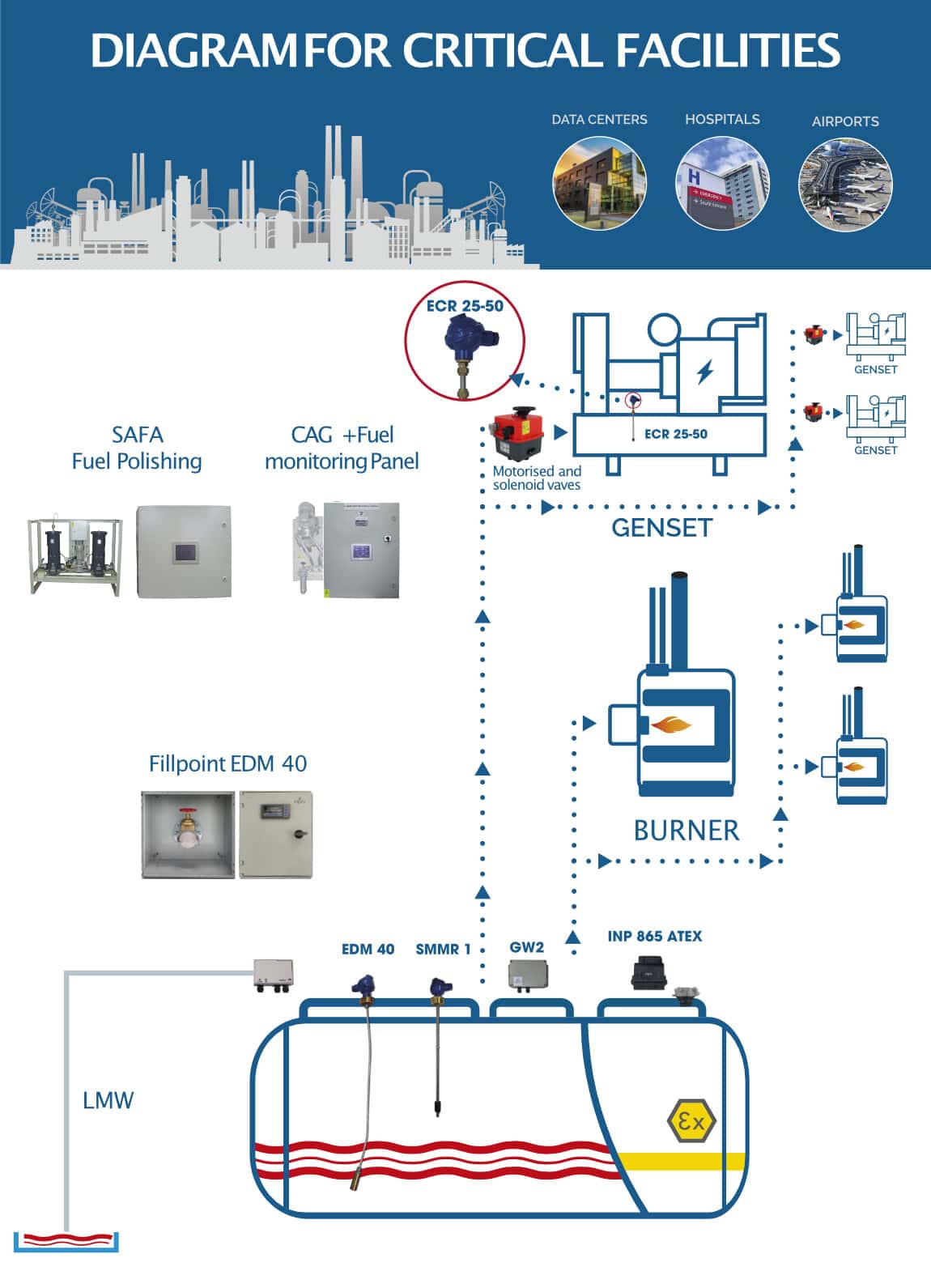

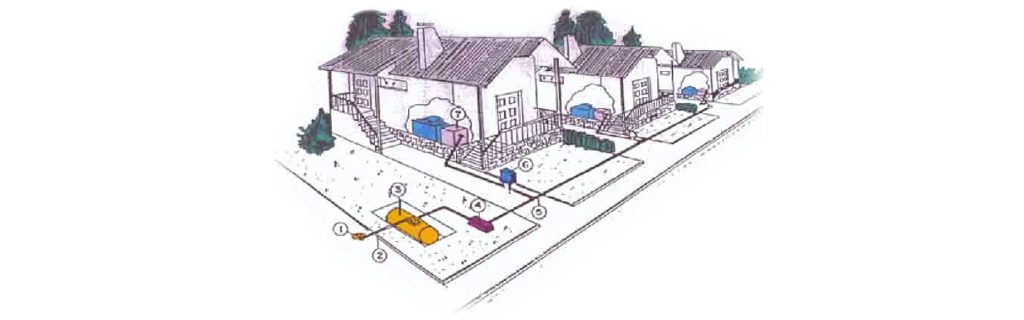

The purpose of the system is to automate the filling of multiple daily tanks, by one or two pressure groups with enough flow to supply the demand of the generating sets, with maximum operational safety and avoid diesel spills in the installation, in addition of transmitting the data to a management system, to monitor the status of the facility.

Solution adopted by INPRO

There are three zones. The first one formed by 2 main tanks (T1-T2), 2 pressure groups of the GP-3200 GET type will suck, one from each tank, independent, and which will supply the first daily tanks; The second one consists of 2 main tanks (T3-T4), 2 pressure groups of the GP-4200 GET type will suck, supplying another two daily tanks; And the third one, 1 main tank (T5) from which 1 pressure group of GP-1500 GET type will suck. All the daily tanks have a double pump system, FP 50 GEW, capable of sending the diesel from the daily tanks to the main tanks, in order to avoid overflows, maintenance work or emptying daily tanks.

EQUIPMENT

- Main tanks control: EDM-40 probe with display

- Leaks detection: DDP-25 interstitial chamber detector

- Pump system: 2 x pressure unit GP-3200 GET (3200L/h)

- 2 x pressure unit GP-4200 GET (4200L/h)

- 1 x pressure unit GP-1500 GET (1500L/h)

- 5 x double pump FP 50 GEW

- Solenoid valves: control the filling process

- PLC control system (CAG+) & Alarm KIT

- Collector tray with leak detector

- Pressure and Level switches SMMR

- Flow meter and Pressure reducing valve