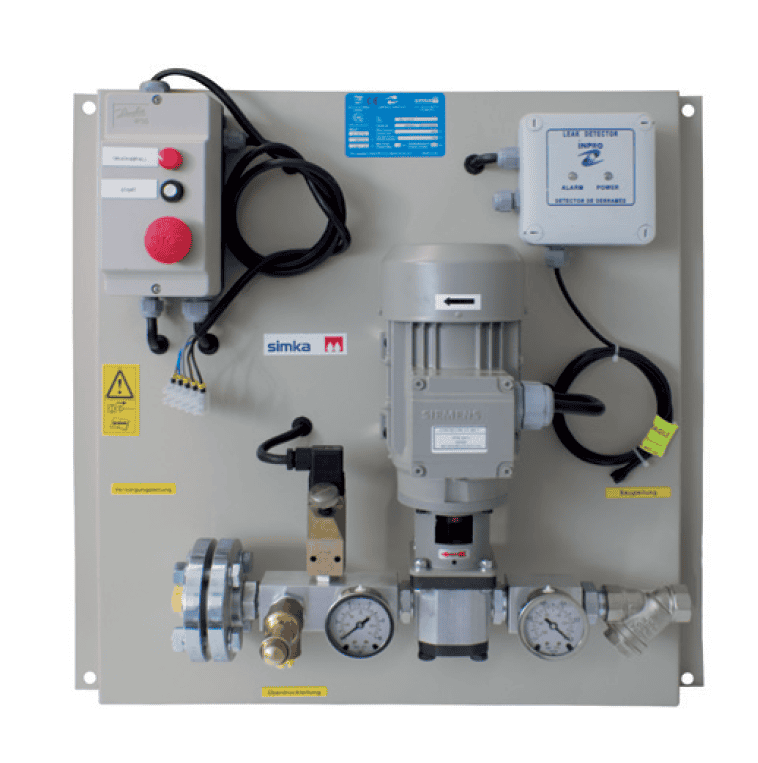

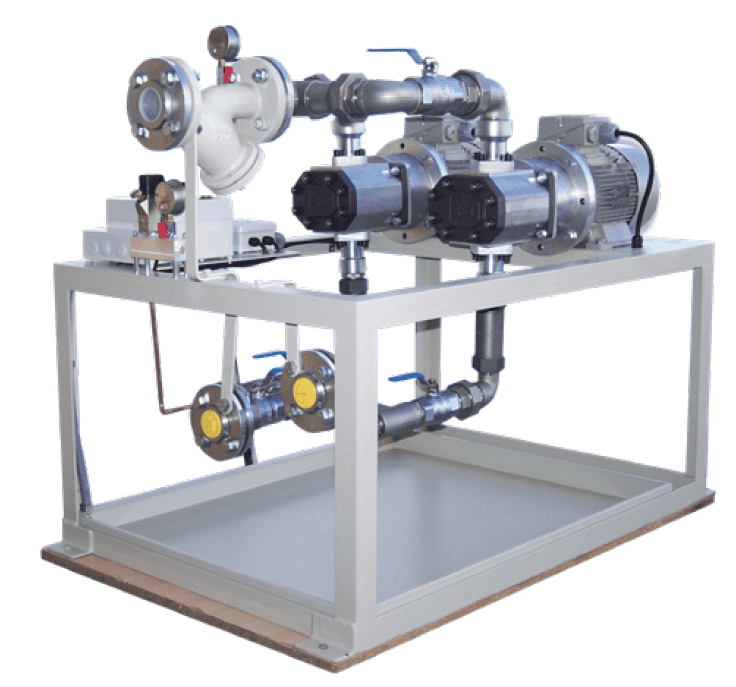

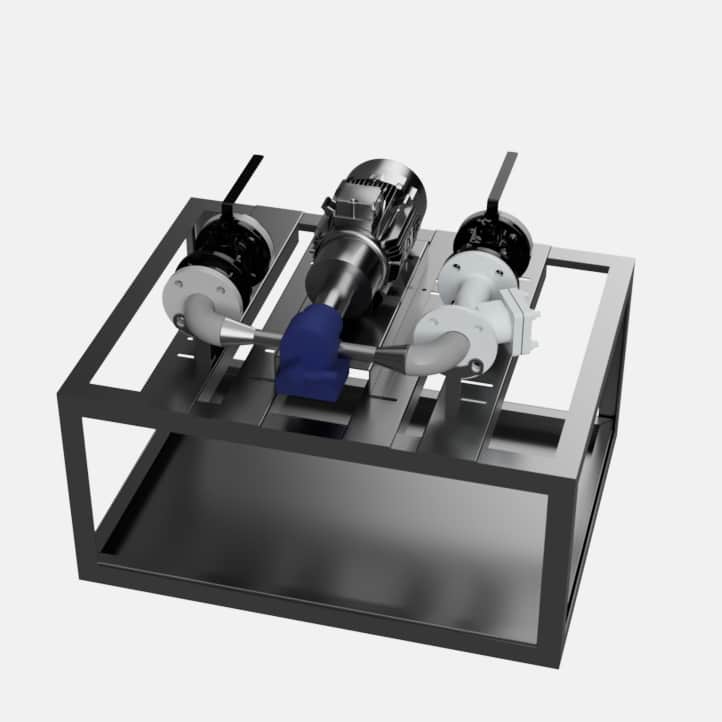

RL N/GE FUEL RING TRANSFER SKID

Fuel Ring Transfer Systems for feeding burners or generators (generator sets). Normal Model

Normal model: flow rates from 100 l/h up to 1,200 l/hApplications & Specific Features

- Pump for ‘Ring Main’ oil transfer systems.

- Single or multiple appliances at same height or varying height.

- Suitable for high output or modulating burners.

- For use on oil supply installations where a GP ‘dead leg’ system is not practical.

- A back pressure relief valve (overflow valve) is required to maintain adequate pressure in the ‘Ring Main’.

- Special RL units available for aggressive or heated non standard fuels.

Accessories and adaptations

- IM system to stop pumps when all burners are off (optional for RL-N)

- Free voltage relay output to control from centralised Building Management System, in kit 3, 4 or 6 signals (2-thermal, motors 1 or 2 ON, low pressure and Leak safety ON).

- GSM alarm system by SMS messages, or connection to modem.

- Adaptation of Pressure Group for high pressure, working conditions of up to 6,5 Kg/cm2

- Leak collector trays with infrared detectors (standard in RL-4 and above).

- Modifications to adapt to specifically regulated environments (tropicalised equipment or ATEX.)

- Solenoid valves with flow limiters, to automate filling in supply tanks for electrical generators.

- Soundproof sheet cabinets with UNE-2

- (*) There is a 230 single-phase version (W) - Threaded Flanges DIN 2566MODEL RL 0 RL 1 RL 2 RL 3 RL 4 RL 5 RL 6 RL 7 RL 8 RL 9 RL 10 MAX. FLOW l/h 100 260 460 900 1400 2100 3400 5300 7500 10500 12000 SUPPLY FLOW l/h 65 150 300 600 900 1450 2300 3600 4900 7000 8000 SUPPLY VOLTAGE VOLT 400* 400 400 400 400 400 400 400 400 400 400 MOTOR POWER KW 0,25 0,25 0,25 0,55 0,55 2,2 3 3 4 4 4 CV 1/3 1/3 1/3 3/4 3/4 3 4 4 5,5 5,5 5,5 MOTOR r.p.m 1420 1420 1420 1420 1420 1420 1420 1420 1420 1420 1420 CONNECTION TO THE HYDRAULIC CIRCUIT (Ø THREAD / Ø MM) SUCTION 1/2” F DN 20 DN 20 DN 25 DN 25 DN 32 DN 40 DN 40 DN 50 DN 50 DN 65 DRIVE 3/8” F DN 20 DN 20 DN 25 DN 25 DN 32 DN 40 DN 40 DN 40 DN 40 DN 50 OVERPRESSURE 1/2” F 1/2” F 1/2” F 3/4” F 1” F DN 32 DN 40 DN 40 DN 40 DN 40 DN 40 MAX. SUCTION m 5 5 5 5 5 5 5 5 5 5 5 SECURITY VALVE OPENS AT: bar 6,5 6,5 6,5 6,5 6,5 6,5 6,5 6,5 6,5 6,5 6,5 MOTOR PROTECTION IP 55 55 55 55 55 55 55 55 55 55 55