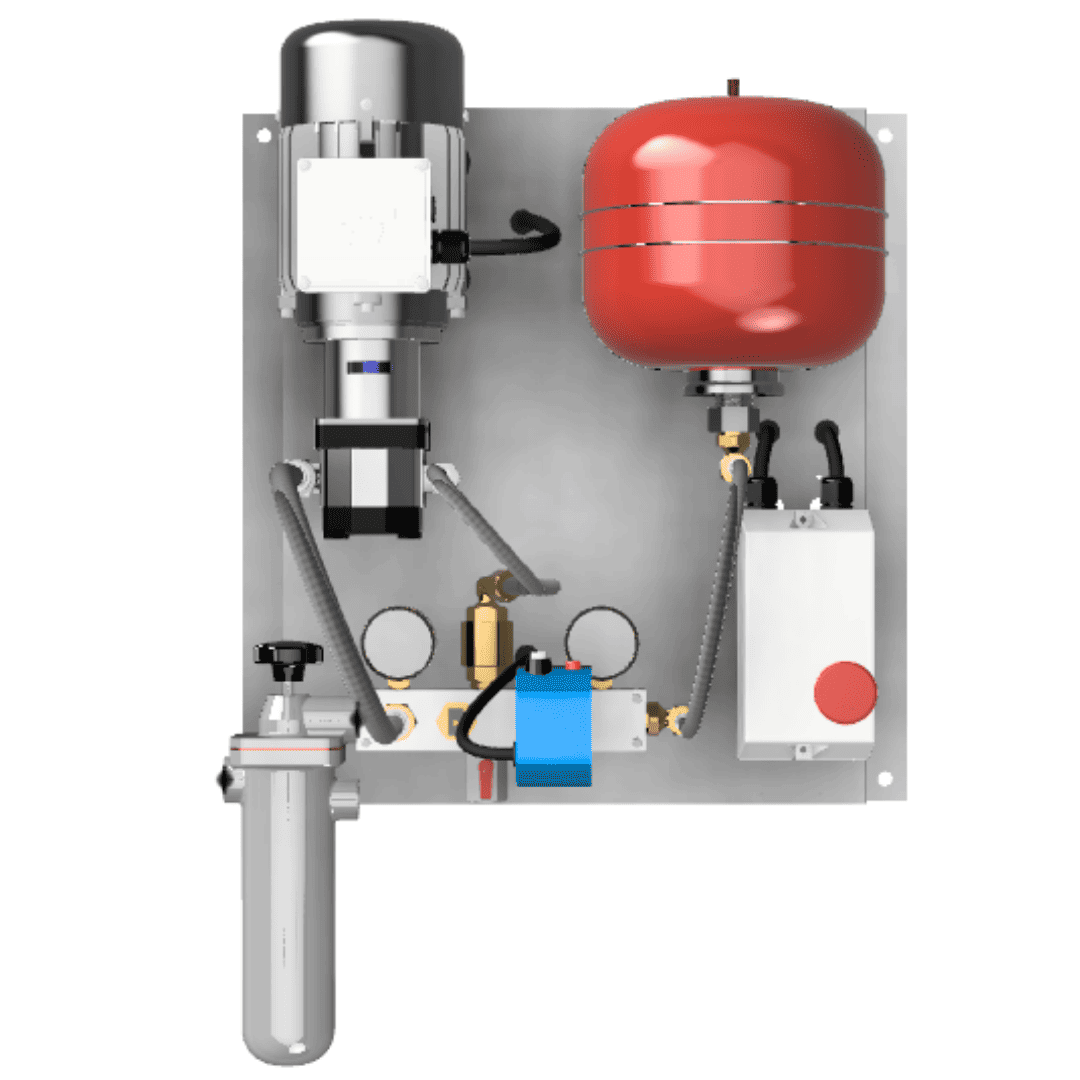

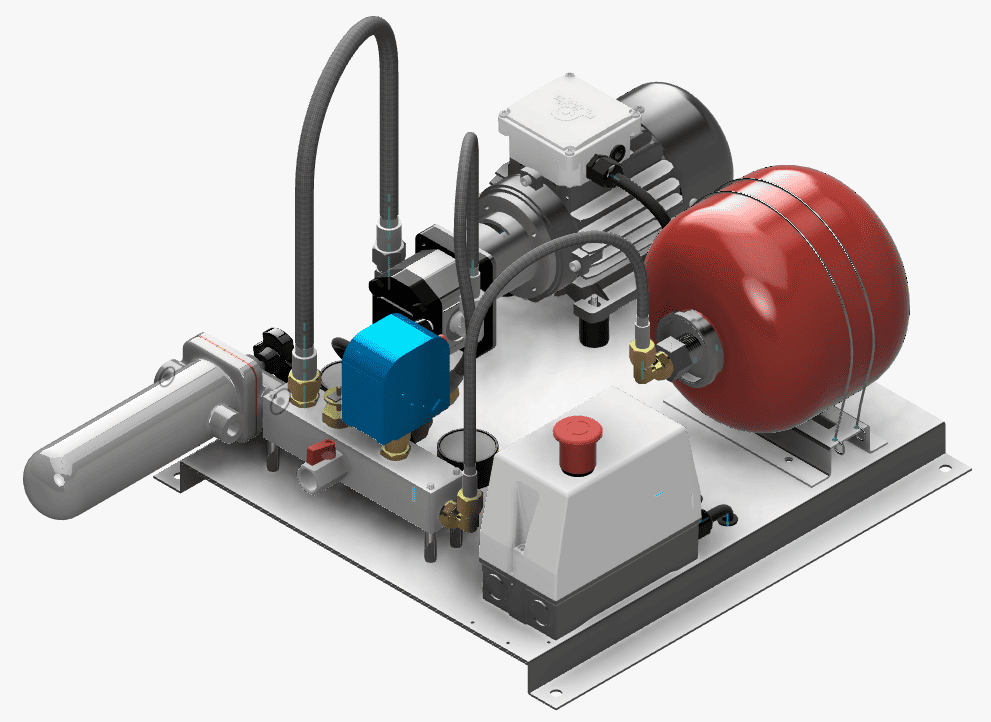

02. GP-70-1500 N

OIL TRANSFER PRESSURE UNITS - From 70l/h to 1500L/h - N

N: 1 pump

Inpro pressure units are equipment used to transfer liquid fuel such as diesel or HVO from a main tank to different consumption points through the pressurization of a line, for the supply of machinery that requires these fuels, such as generators (power generators) or burners for boilers in buildings..

There are several sizes and configurations of equipment, in which the flow rate that can control the equipment can vary (from 30l/h to 12,000 l/h), the maximum pressure at which they can work, with the possibility of redundancy in some components, and other parameters such as the type of power supply..

It can be Normal or Twin equipment that duplicates critical components to increase reliability..

Application area example

Small units (from 30l/h to 1,500l/h) can be used for:- The supply of boilers in single-family houses.

- Community of neighbors buildings

- Small installations.

- Large buildings requiring 24h/7 electricity

- Data Centers

- Hospitals

- Airports

- Malls...

Applications & Specific Features

- Multiple burner, appliances or service tanks supplied with one GP pressure unit.

- Appliances installed at different heights.

- Modulating burners when using the Inpro Oil Burner Inlet Assembly (see Datasheet).

- Oil Supply installation using ‘dead leg’ pipework. GP unit does not need external controls.

- GP units operate on an internal pressure switch only pumping fuel when required.

- Pressure regulators may be required at oil inlet to burners/appliances.

- Limited suction lift may require GP unit to be sited near the oil tank.

Accessories and Adaptations

- Free voltage relay output to control from centralised Building Management System, in kit 3, 4 or 6 signals (2-thermal, motors 1 or 2 ON, low pressure and Leak safety ON).

- GSM alarm system by SMS messages, or connection to modem.

- Adaptation of Pressure Group for high pressure, working conditions of up to 6 Kg/cm2

- Leak collector trays with infrared detectors (standard in GP-800 and GP-1500).

- Modifications to adapt to specifically regulated environments with tropicalised equipment or ATEX.

- Solenoid valv

Caractéristiques techniques

| MODEL | GP-70 N | GP-130 N | GP-200 N | GP-300 N | GP-500 N | GP-800 N | GP-1500 N | |

|---|---|---|---|---|---|---|---|---|

| FLOW | l/h | 70 | 130 | 200 | 300 | 500 | 800 | 1500 |

| CONNECTION TO THE HYDRAULIC CIRCUIT (Ø THREAD / Ø mm) | SUCTION | 1/2” F | 1/2” F | 1/2” F | 3/4” F | 3/4” F | 1” F | 1” F |

| DRIVE | 3/8” F | 3/8” F | 3/8” F | 1/2” F | 1/2” F | 1/2” F | 3/4” F | |

| POWER SUPPLY | VOLTS | 230/400 tri-phase* | 230/400 tri-phase* | 230/400 tri-phase* | 230/400 tri-phase* | 230/400 tri-phase | 230/400 tri-phase | 230/400 tri-phase |

| MOTOR POWER | C.V. | 1/4 | 1/3 | 1/3 | 1/3 | 1/2 | 3/4 | 1½ |

| KW | 0,18 | 0,25 | 0,25 | 0,25 | 0,37 | 0,55 | 1,1 | |

| MAX. PRESSURE | kg/cm2 | 3,5 | 3,5 | 3,5 | 4 | 4 | 4 | 4 |

| SAFETY VALVE OPENS AT: | kg/cm2 | 4 | 4 | 4 | 4,5 | 4,5 | 4,5 | 4,5 |

| MOTOR PROTECTION | IP | 55 | 55 | 55 | 55 | 55 | 55 | 55 |

GP Videos:

| Pressure switch regulation | GP troubleshooting |