The problem of fuel management in data centres

The real challenge does not always lie in the generators, but in an inadequate fuel management system. This aspect, often overlooked during project design and implementation, can be the cause of delays in generator start-up or synchronisation.

The main power supply in a data centre is typically the local power grid. In the event of a power outage, a diesel generator power plant is activated within the data centre, which includes fuel storage and handling with underground tanks and a network of pipelines connected to the generator room.

India’s growing data demand and energy challenge

The demand for data in India is growing exponentially, leading to a rapid increase in the number of data centres. New hyperscale facilities require much more power and are designed to ensure Tier IV uptime levels. Unfortunately, the country’s power grid has not kept pace in terms of capacity, reliability and quality of power supply. As a result, more than 95% of data centres in India often rely on diesel generator (genset) backup power systems.

Implementing a robust and efficient fuel management system is essential to ensure continuous uptime and avoid costly data centre outages.

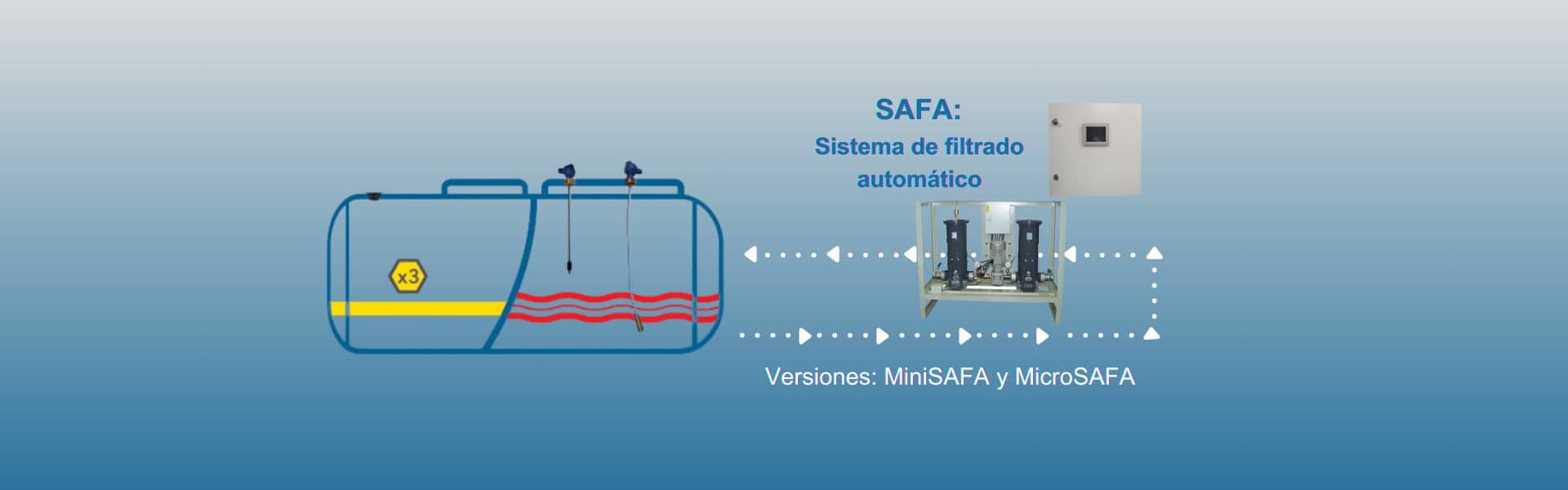

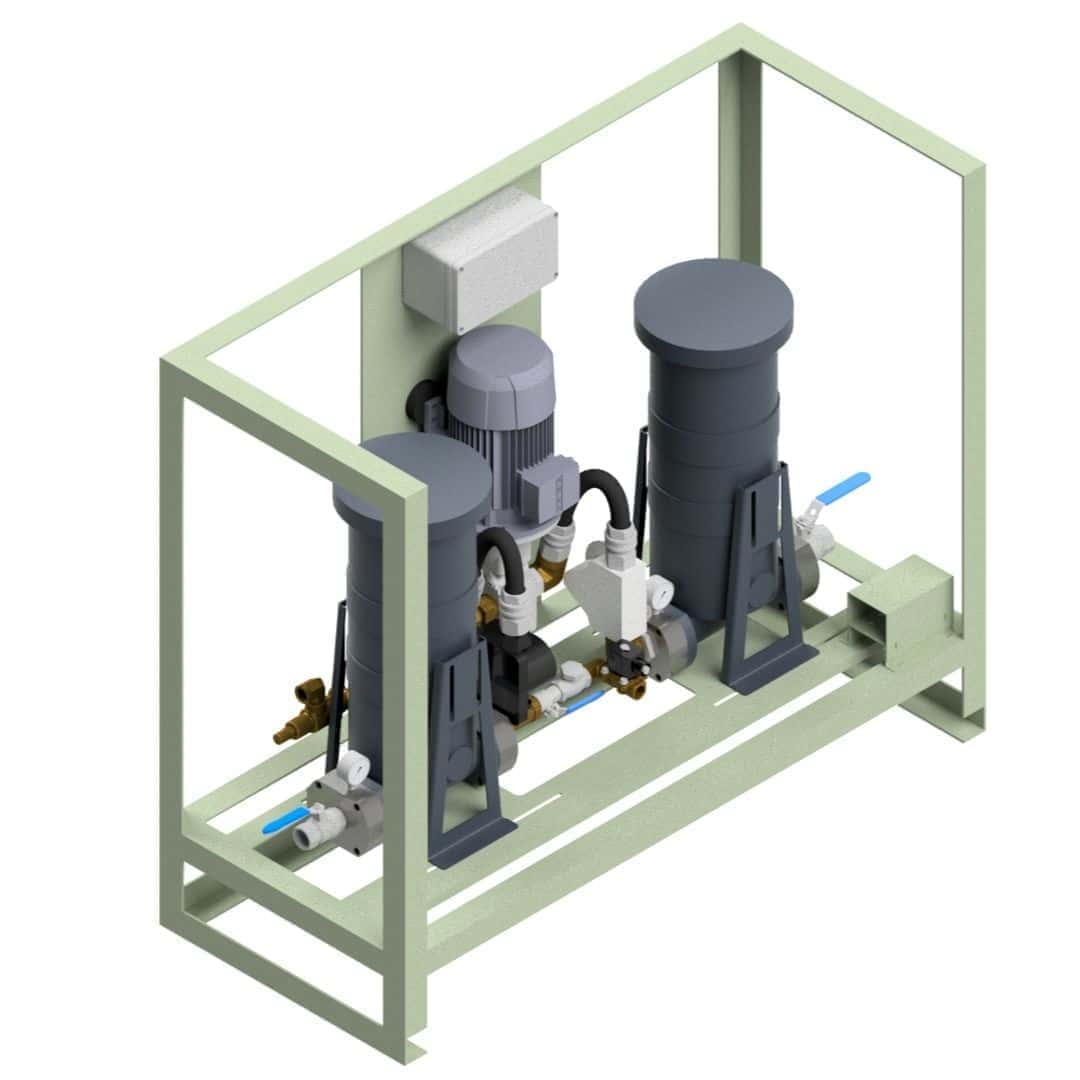

Automatic fuel polishing system, such as our SAFA

If generators do not start or synchronise quickly, it may be due to a poorly designed fuel management system. Diesel fuel deteriorates over time, which can lead to sludge formation, clogged filters and other problems. In addition, the use of “clean” fuels with low sulphur content, while beneficial in reducing emissions, may break down faster if stored for long periods.

An automated fuel management system provides critical controls at various stages of fuel handling, from receipt at the unloading bay to final delivery to the gensets. This improves efficiency, reliability and cost optimisation.

Source of information: Data Center Dynamics, November 2019

Can it be adapted to data centres?

For new data centres with hyperscale capabilities and Tier IV reliability, the use of a complete fuel management system is mandatory. However, older data centres can also benefit from this upgrade to avoid costly future outages.

Benefits of upgrading

-

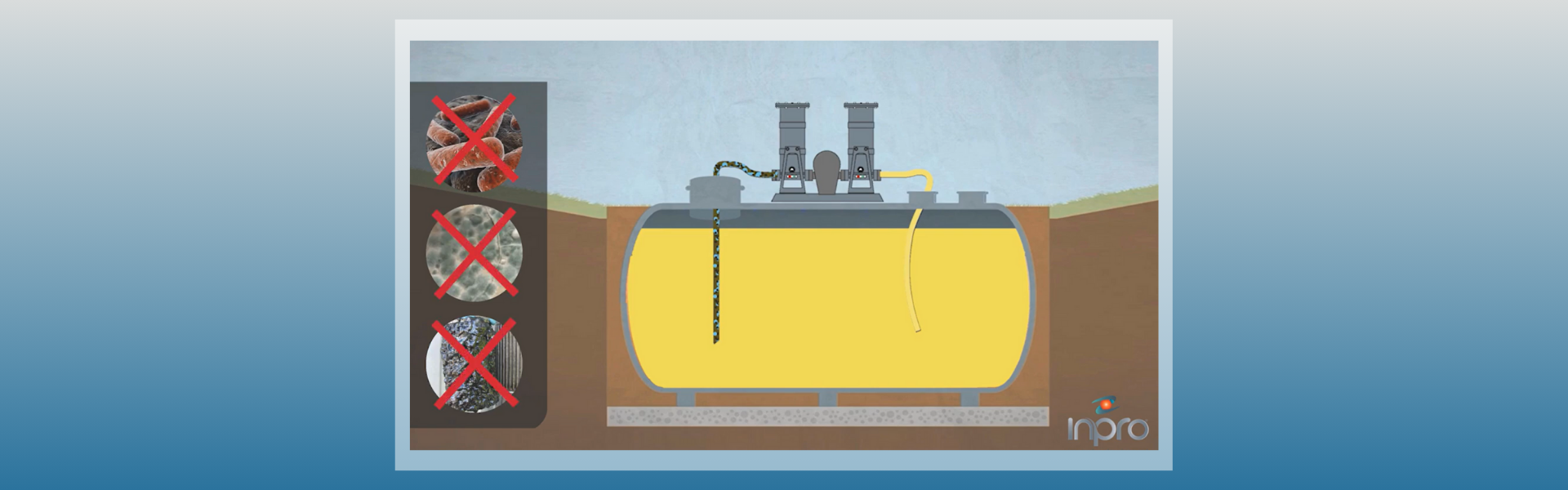

Reduction of pollutants and residues in fuel tanks: Over time, the tanks accumulate impurities that can cause genset failures.

-

Detection of leaks and fuel wastage: Older manual systems are prone to errors and security lapses.

-

Redundancy in the pipeline network: A single point of failure is a risk that can be avoided with an up-to-date fuel management system.

-

Optimisation for future expansion: An inadequate system may prevent capacity expansion and Uptime certification.

Main objective of the fuel management system: fuel filtering and polishing system (at Inpro the SAFA)

One of the key objectives of the fuel management system is to provide clean and filtered fuel throughout the system, from the storage tank to the day tanks. The main advantages of a fuel filtering and polishing system are:

-Reduced maintenance costs

-Reduced likelihood of fuel injector failure

-Reduced noise and smoke during generator operation

When is a SAFA automatic polishing system necessary?

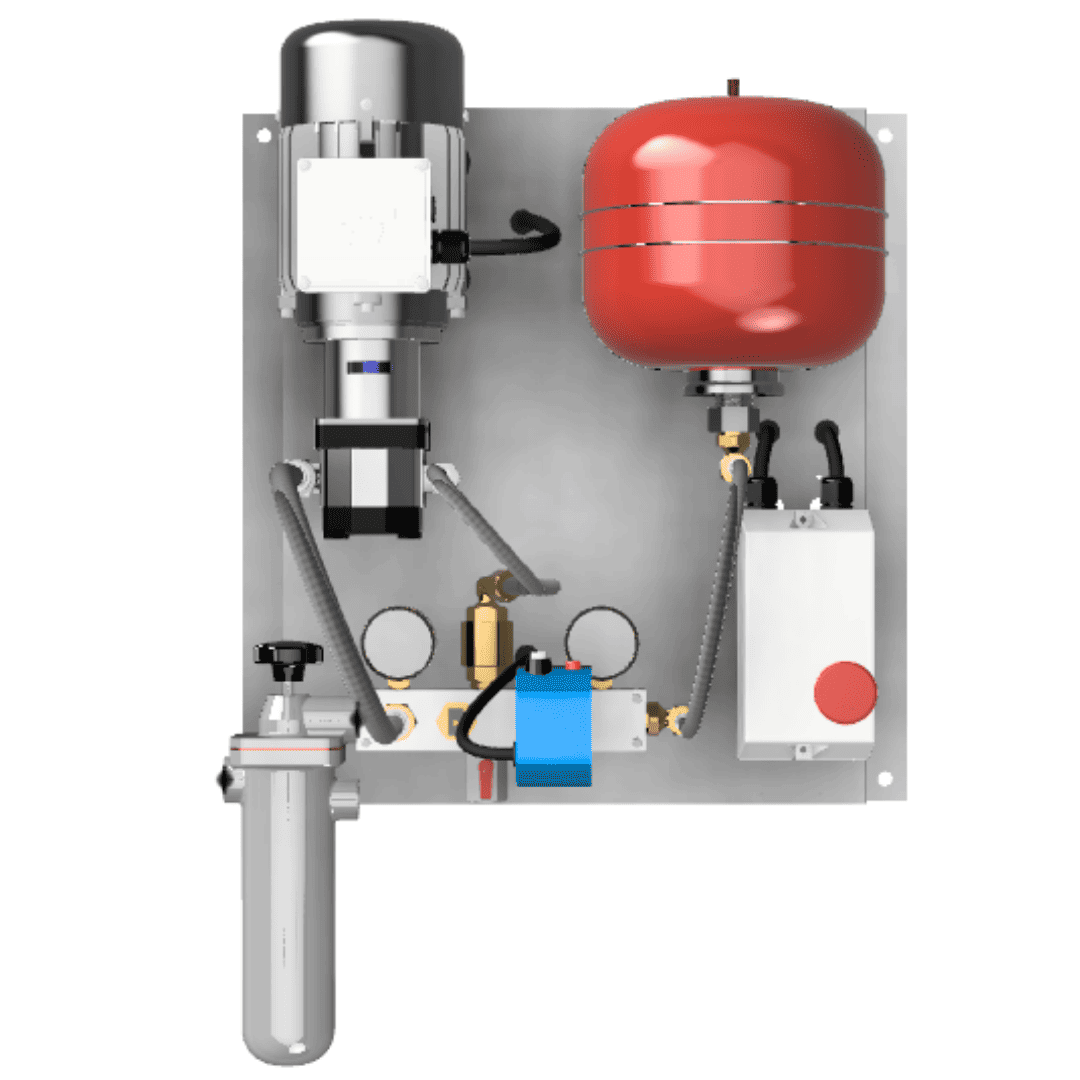

Our product range of automatic filtering and polishing systems for fuel treatment covers every filtration need, thus helping to avoid disruptions in data centres:

SAFA

For multiple and large fuel storage tanks, up to “n” main tanks. Fixed or portable execution available.

MINISAFA

For single and large fuel storage tanks, up to 50000 l. volume. Fixed or portable execution available.

MICROSAFA

For day tanks up to 2000 l.

Examples of our fuel filtering and polishing equipment installed on projects:

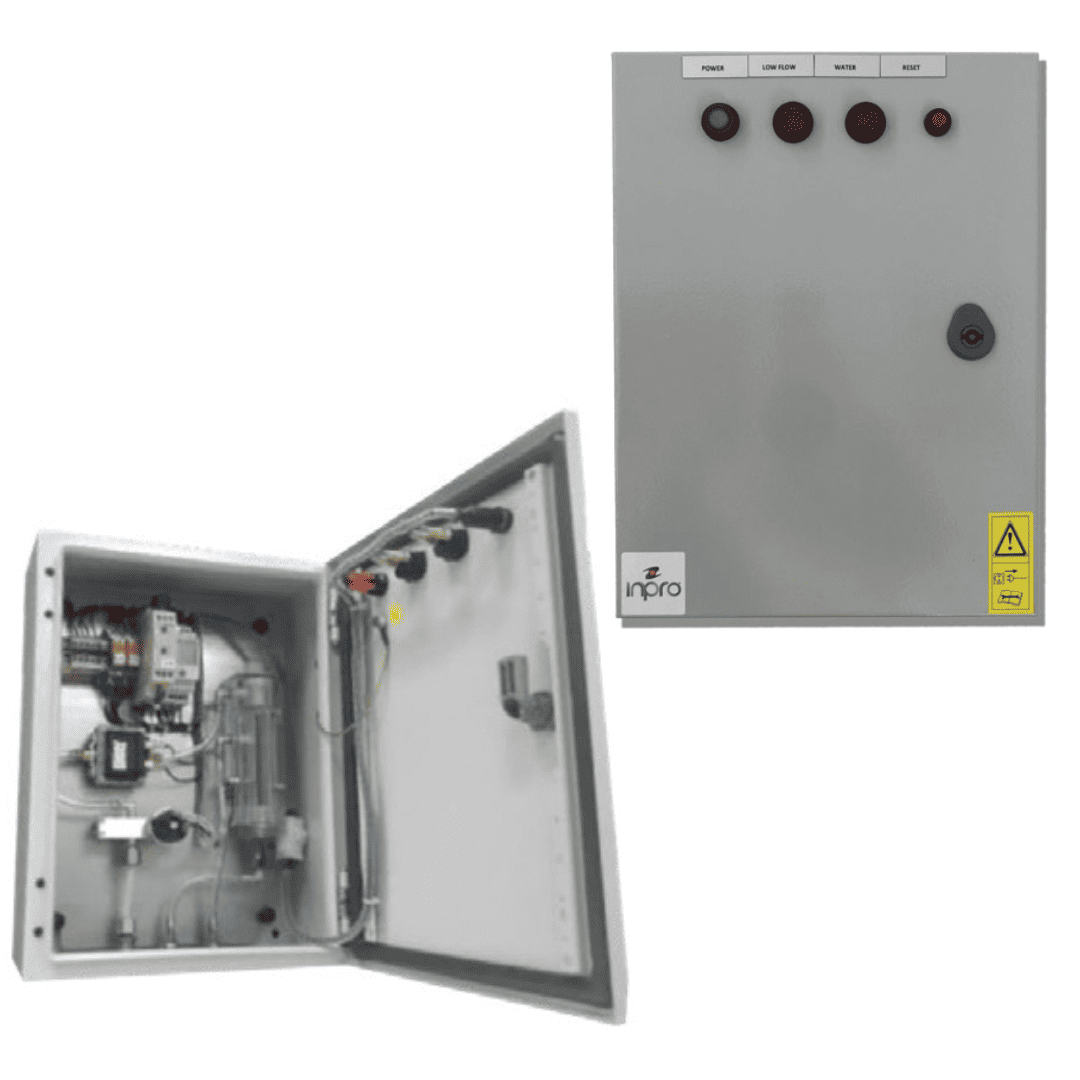

Safety and security

The fuel management system should incorporate technologies such as fusible link valves to quickly evacuate tanks in case of fire. In addition, it should include a leak detection system connected to the building management system (BMS) to raise alarms.

Inpro’s fuel transfer units includes products designed for leak detection:

Other articles about Polishing and Filtering Systems

Automatic fuel polishing system: SAFA, MiniSAFA and MicroSAFA

The function of a SAFA polishing system is to maintain the fuel in optimal condition in an automated way.

Fuel management: polishing systems prevent data centre blackouts

The real challenge does not always lie in the generators, but in an inadequate fuel management system.

Maximising Efficiency and Economy: The Automatic Fuel Polishing System

In applications where fuel is required, the quality of the fuel is critical to optimal performance….

Inpro case studies in data centres

At Inpro we have extensive experience in the execution of data centre projects. We develop customised engineering solutions for power generation plants in critical facilities in various countries.

Information about data centres

For more information about our products, services and data centre projects, please send an email to info@inprord.com or fill in the form below: