Rising gas prices: why switch to diesel and HVO for a more sustainable future??

Gas prices continue to spiral upwards, affecting industry as well as households and commercial buildings. The global energy crisis, uncertainty in the markets and reduced gas supplies to Europe have pushed up costs considerably, causing many businesses and individuals to look for more efficient and economical alternatives.

Factors such as weather and Asian demand for Liquefied Natural Gas (LNG) will continue to influence costs. On 1 January 2025, the closure of the pipeline across Ukraine increased the EU’s dependence on Liquefied Natural Gas, which could further strain the market. In addition, the rise in gas prices has a direct impact on electricity prices, despite its lower use in thermal power plants.

Source of information: El País, February 2025.

Diesel or HVO as an alternative to gas-fired equipment in industry

During the 2023 crisis, many companies looked for alternative solutions to reduce costs, and one of the most viable options was to switch to diesel. Stability in supply and the availability of infrastructure for storage and distribution made diesel a reliable alternative in a context of energy uncertainty.

At Inpro we are specialists in the design and manufacture of fuel transfer units, we offer equipment to guarantee efficiency, savings and sustainability. In addition, our equipment is compatible with HVO (hydrotreated vegetable oil), a more sustainable fuel.

Types of facilities and their exchange options

There are three main types of heating and energy installations:

1. Gas only installations (not recommended):

They are highly dependent on volatile gas prices and are subject to supply risks and possible tariff increases.

2. Mixed installations (gas and diesel):

They are more flexible and allow alternating the use of both fuels, which provides room for manoeuvre in the face of rising gas prices.

3. Fuel only installations:

They are the most stable and economical option in the long term, with the ability to easily adapt to renewable fuels such as HVO without the need for major modifications.

Opting for a Mixed or 100% Diesel Installation

If you currently have a mixed (gas and fuel) installation, making the transition to a fully fuel-based system is a smart move.

-

Immediate savings: You will reduce dependence on gas and its unstable prices.

-

Security of supply: Diesel is more accessible and is not subject to geopolitical restrictions like gas.

-

Lower future investment: By converting your installation to diesel, you are ready to take the next step towards using HVO, a 100% renewable fuel.

If you have an all-gas installation, switching to a mixed installation with fuel may be an intermediate option to reduce costs.

HVO: turn your installation into a sustainable, future-proof energy solution with minimal changes

HVO (hydrotreated vegetable oil) is a renewable fuel that reduces CO2 emissions by up to 90% without the need to modify existing infrastructure. With a diesel system in place, the transition to HVO is as simple as changing the fuel, with no need to replace equipment or make costly investments.

HVO Ready Products: Inpro equipment is compatible with hydrogenated vegetable oil

At Inpro we like to take risks and that is why we have opted for the use of hydrogenated vegetable oil with our HVO Ready products. Our equipment automatically transfers the HVO from the tanks to the consumption points.

In addition, we have extensive experience in providing energy solutions for critical facilities with liquid fuels, such as HVO, as our equipment is 100% compatible with this biofuel:

Data centres increasing use of hydrogenated vegetable oil (HVO)

Inpro bets on hydrotreated vegetable oil (HVO) on its products

Research study certifies that Inpro manufactures 100% HVO-compatible equipment

Germany wants to lead the use of HVO

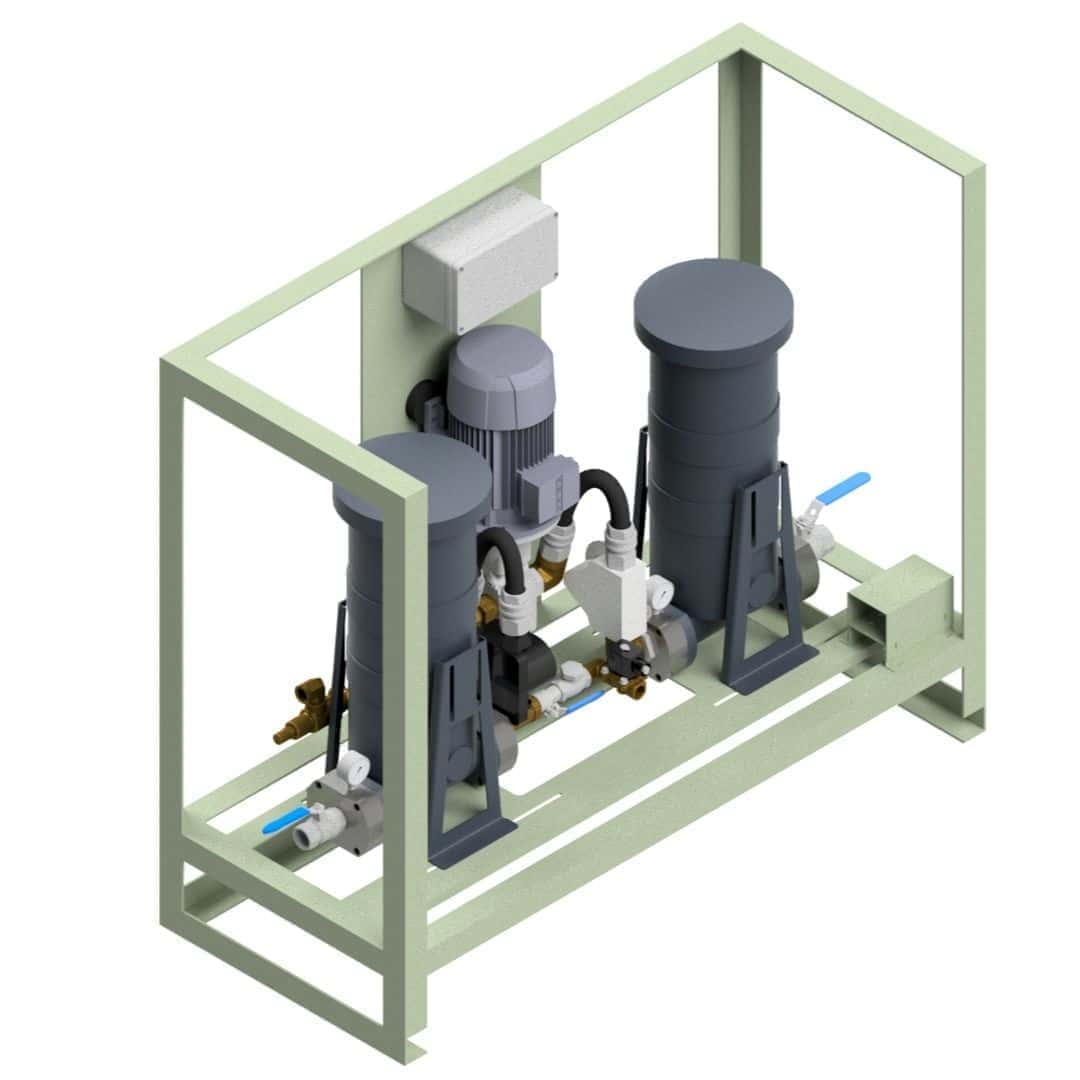

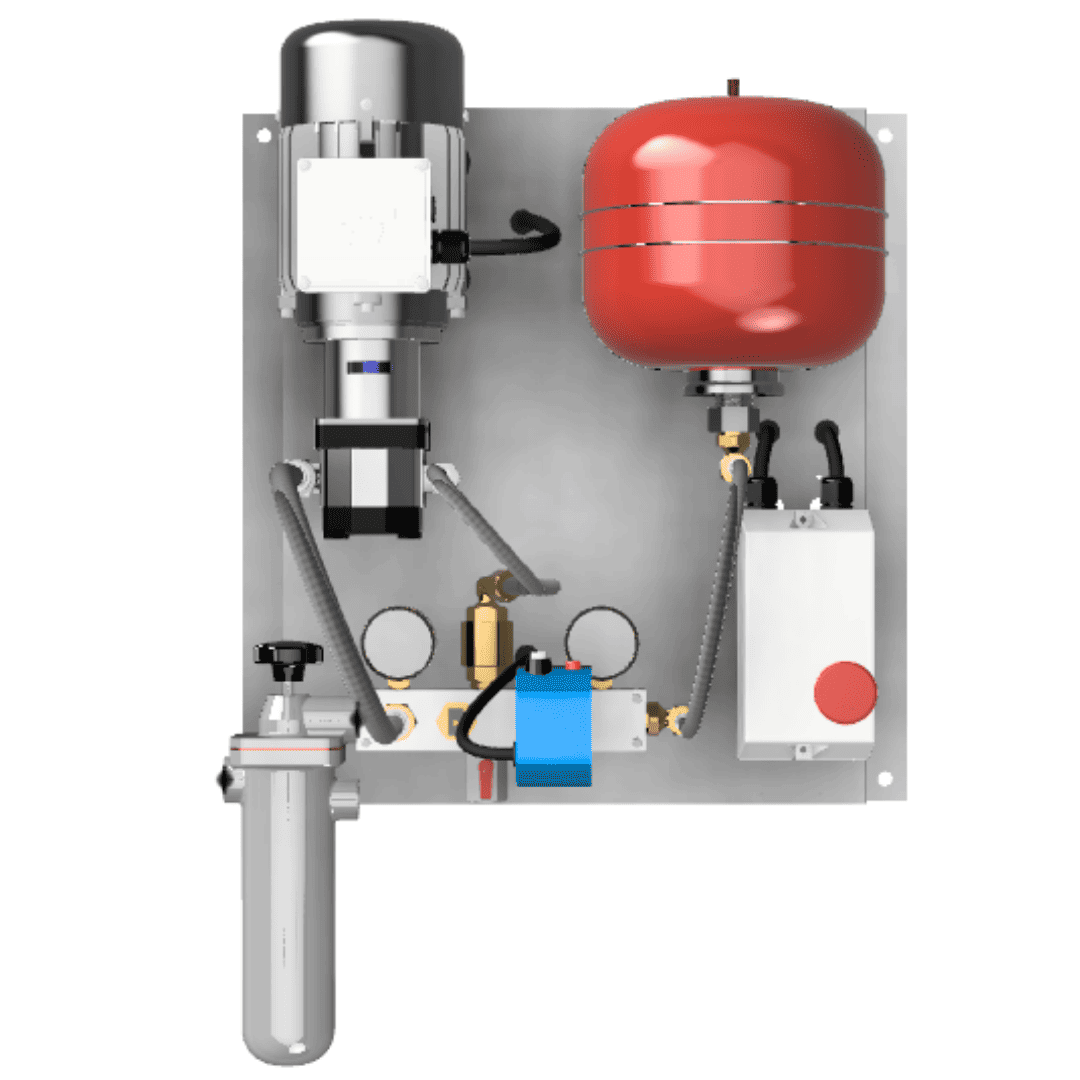

INPRO’s solutions: Diesel Fuel Racking Systems

For residential and industrial heat production (burners and boilers)

At Inpro, we design and manufacture specialised solutions for the storage, measurement and control of diesel in various applications. Our aim is to offer you a safe, reliable and economical alternative for powering heating installations in homes, buildings, offices, hotels and hospitals, as well as industrial systems.

Fuel transfer systems to ensure a constant supply.

Monitoring and control equipment for hydrocarbon and other fluid reservoirs.

Consumption control systems for burners and emergency generators.

A cost-effective and sustainable solution for industrial heat production

Fuel remains a more economical and stable option than gas for residential and industrial heat production: burners and boilers. With the advantage that its infrastructure is easily adaptable to HVO, the renewable fuel of the future. By making the switch now, you will not only reduce costs, but you will be investing in a sustainable solution without the need for significant modifications to your installation.

Discover some of our products:

Inpro case studies in residential and industrial heat production

Installations for automatic feeding of staged or modulating burners, in single-tube systems with start-up by pressure controller, or ring recirculation. From small single-family installations to multiple burner systems, with high simultaneity coefficients, higher redundancy requirements but the same safety at the first level.

Would you like to know more about our projects?

If you want to become a distributor of our products or you need information about our projects in critical facilities, either nationally in Spain (ventas@inprord.com) or internationally (export@inprord.com), you can contact us by filling out this form: