The Automatic Fuel Polishing System: SAFA

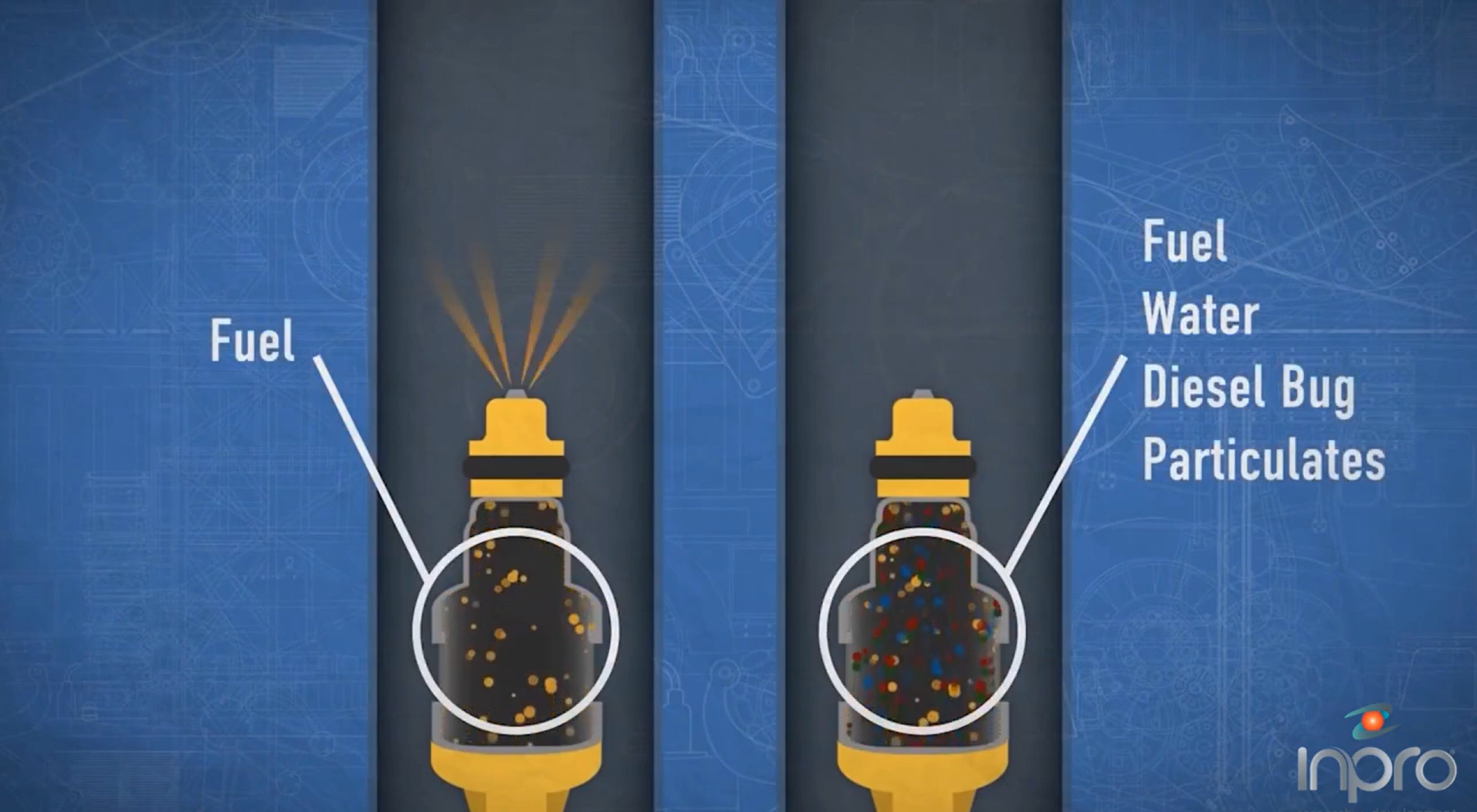

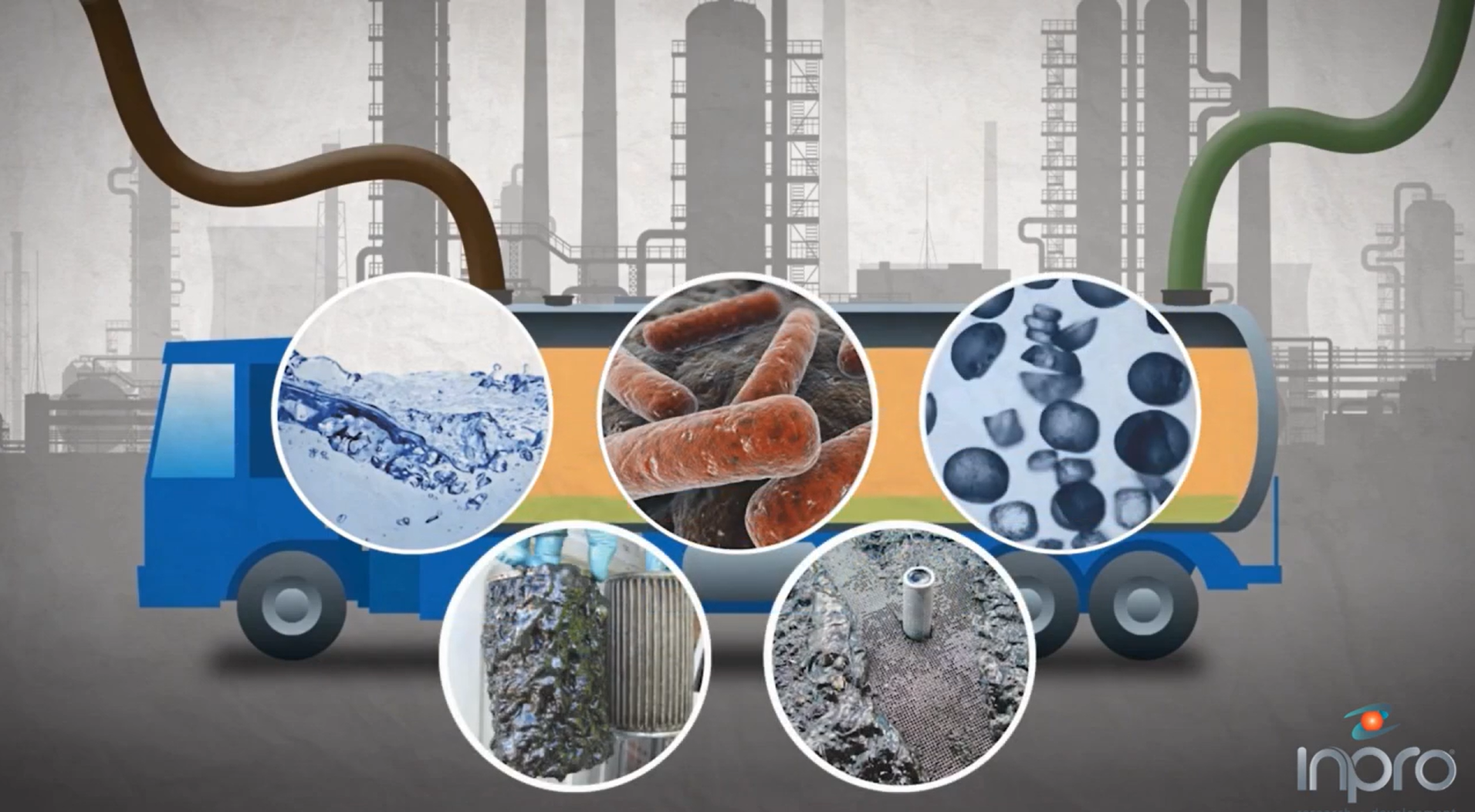

In applications where fuel is required, fuel quality is critical to the optimal performance of engines, generators and heating systems. However, the presence of contaminants such as water can wreak havoc on the efficiency and service life of this equipment, and can lead to problems such as:

-

Reduced heat capacity: Water has a much lower heat capacity than diesel fuel. When water is mixed with fuel, it dilutes its energy content, resulting in less efficient combustion and reduced engine, generator or boiler efficiency.

-

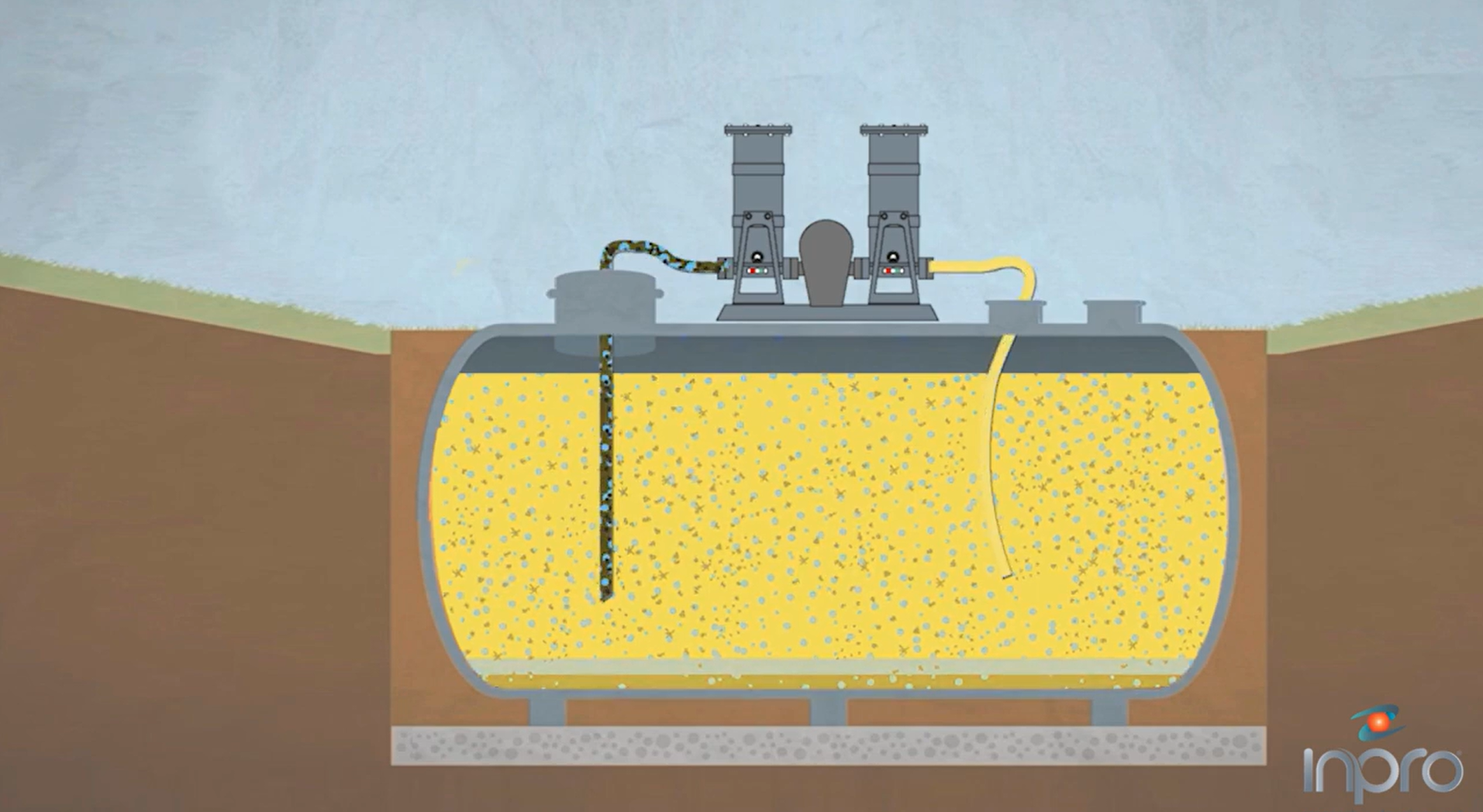

Bacterial growth: Water in fuel can create an environment for the growth of bacteria and micro-organisms that can cause a variety of problems.

-

Biomass: Growing bacteria produce biomass as part of their metabolism. This biomass can accumulate and form sediment in the fuel, clogging filters and fuel lines.

Video: The importance of installing a fuel filter in your fuel tank

-

Organic acids: During their metabolism, bacteria can produce organic acids as by-products. These acids can cause corrosion of metal components in the fuel system, leading to sediment formation and system degradation.

-

Gases: Some bacteria can produce gases as by-products of their metabolism. These gases can accumulate in the fuel system and affect its normal functioning.

-

Chemical compounds: In addition to organic acids, bacteria can also produce other chemical compounds as by-products of their metabolism. These compounds can contribute to fuel degradation and sediment formation.

Bacteria in diesel fuel can not only feed on fuel components, but can also produce a variety of debris that can negatively affect fuel quality and stability, as well as the integrity of the fuel system in general. For this reason, it is crucial to take measures to prevent bacterial growth and maintain diesel fuel quality.

From an economic point of view, allowing the formation of bacteria may generate:

-

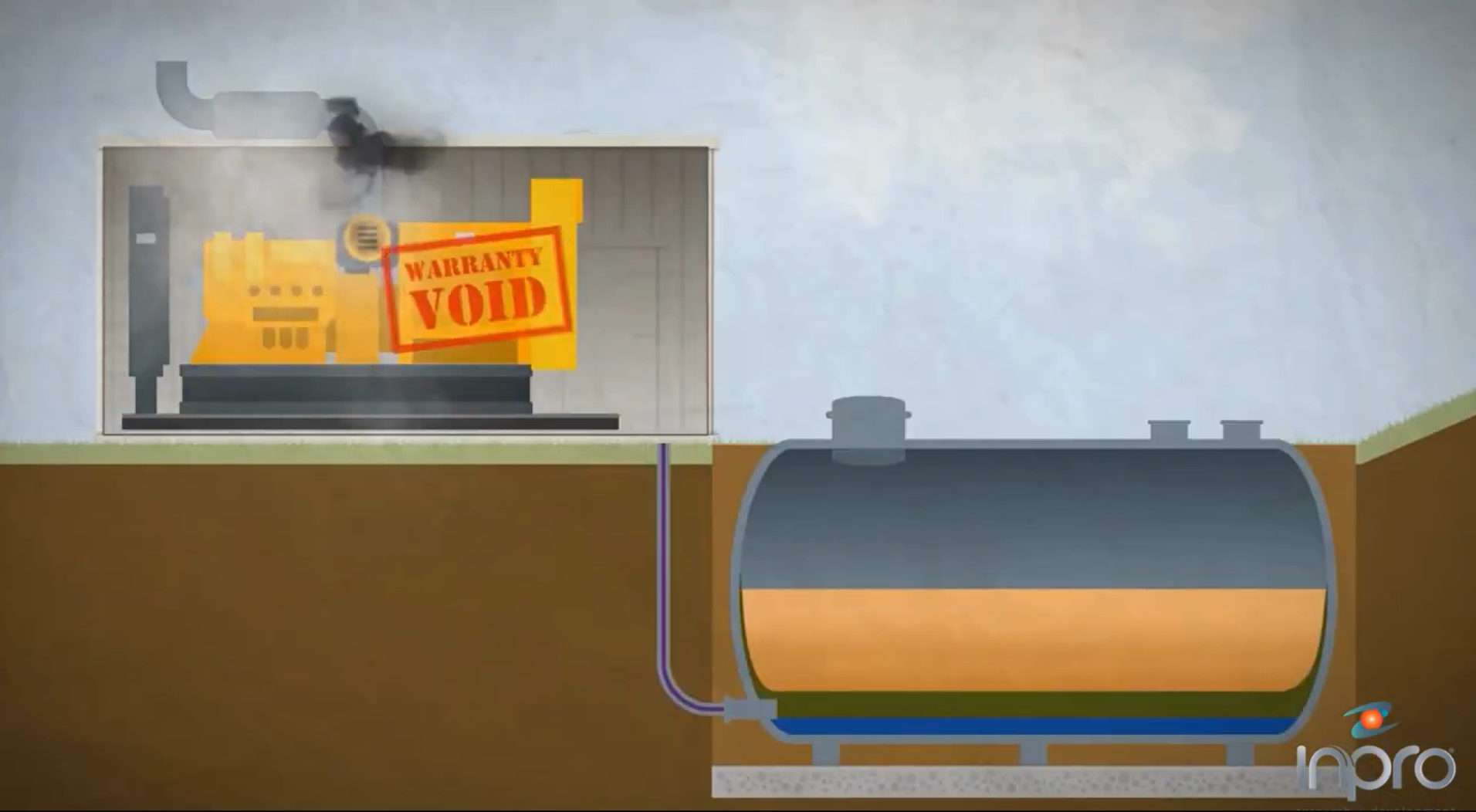

The need to change filters more frequently with the corresponding cost of maintenance work and consumables.

-

Incorrect operation of the systems that require the fuel, such as engines and boilers, generating losses due to low efficiency.

-

Losses of all stored fuel. If bacterial growth is very pronounced, fuel degradation can easily lead to the need to dispose of all fuel.

-

When fuel degradation reaches the point where it has to be disposed of, the entire system needs to be thoroughly cleaned, which results in a significant period of suspension of service and high associated maintenance costs.

-

If the fuel system has been subjected to prolonged periods of contamination, system degradation in the form of rust is likely to have occurred, requiring the replacement of components, or even a complete replacement of the entire system, resulting in avoidable investment.

How to prevent such situations from occurring?

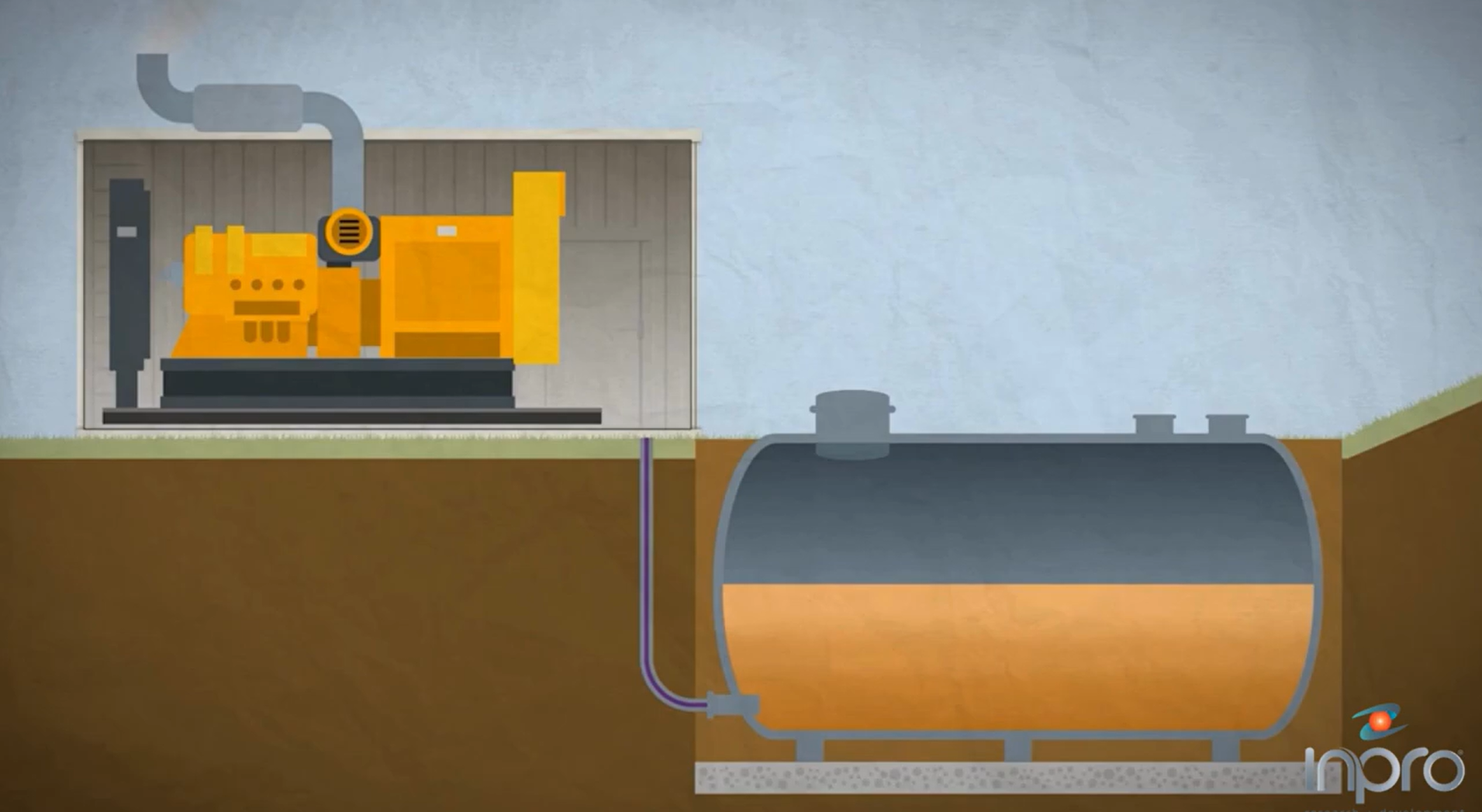

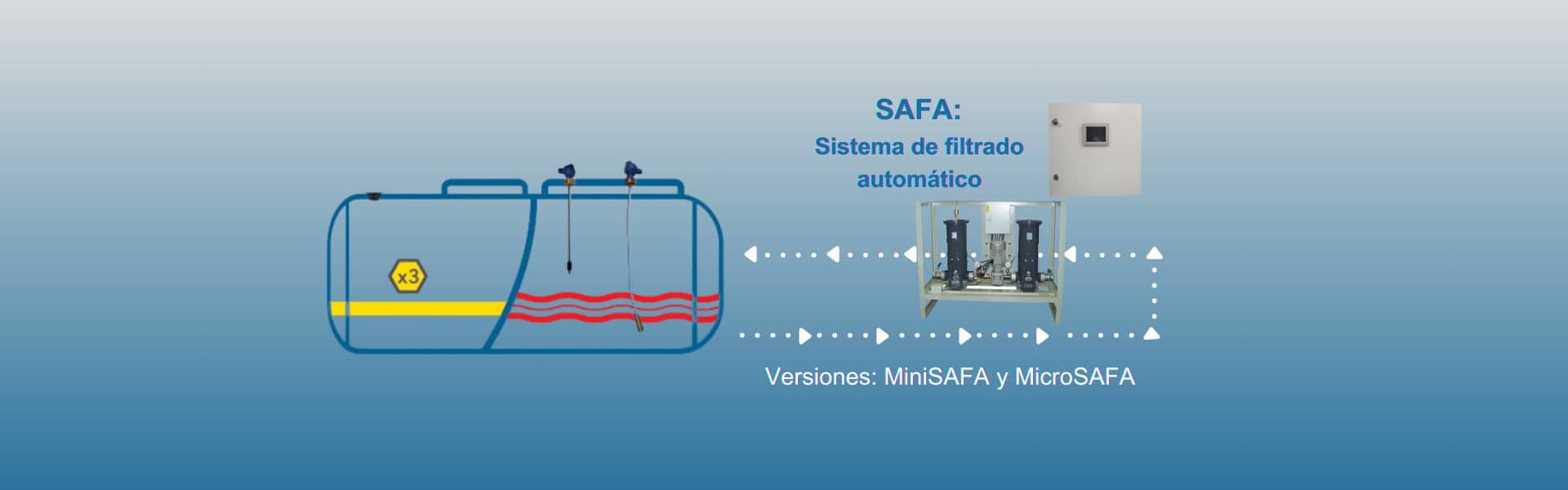

The Automatic Fuel Polishing System (AFAPS) is a system that provides a comprehensive solution to ensure a clean and contaminant-free fuel supply and avoid all the problems that can generate this situation.

The speed of bacterial propagation varies with respect to fuel, humidity and ambient temperature and other factors related to the bacterial biodiversity of the area where the installation is located, but a SAFA system allows these filtering tasks to be carried out automatically, and can be programmed to act effectively and efficiently according to the conditions of the installation, without increasing maintenance costs.

This is where SAFA becomes an invaluable ally. By removing water and solid particles from the fuel. SAFA not only prevents corrosion and clogging problems, but also actively combats bacterial growth. This not only protects equipment and improves its performance, but also contributes to more efficient and cost-effective operation.

In short, the Automatic Fuel Polishing System not only protects equipment from the hazards of water and solid particles, but also actively combats bacterial growth, preserving the quality and integrity of fuel and system components. With SAFA, efficiency and economy go hand in hand, providing peace of mind and reliable results in any operating environment.

Filters and Automatic Fuel Polishing Systems

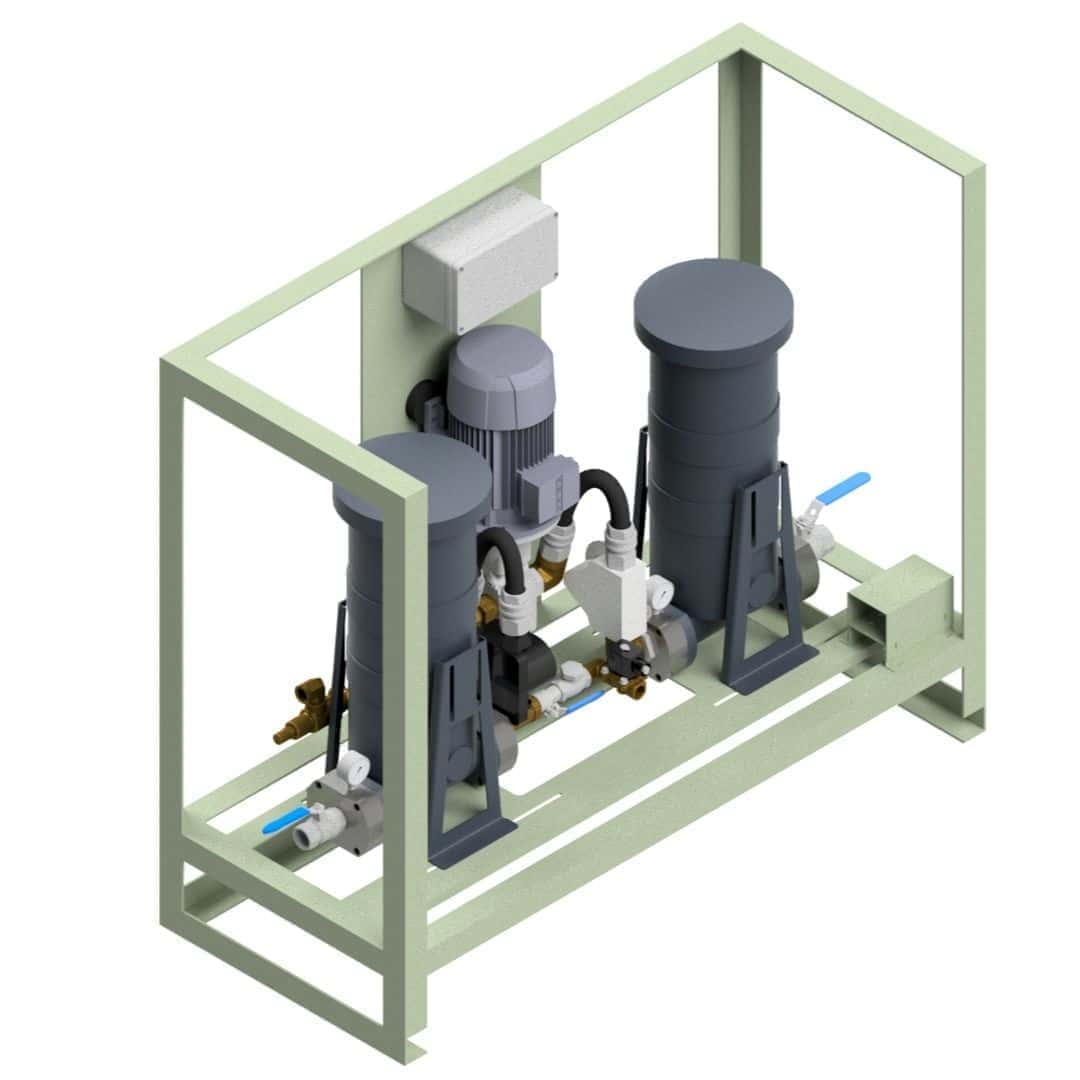

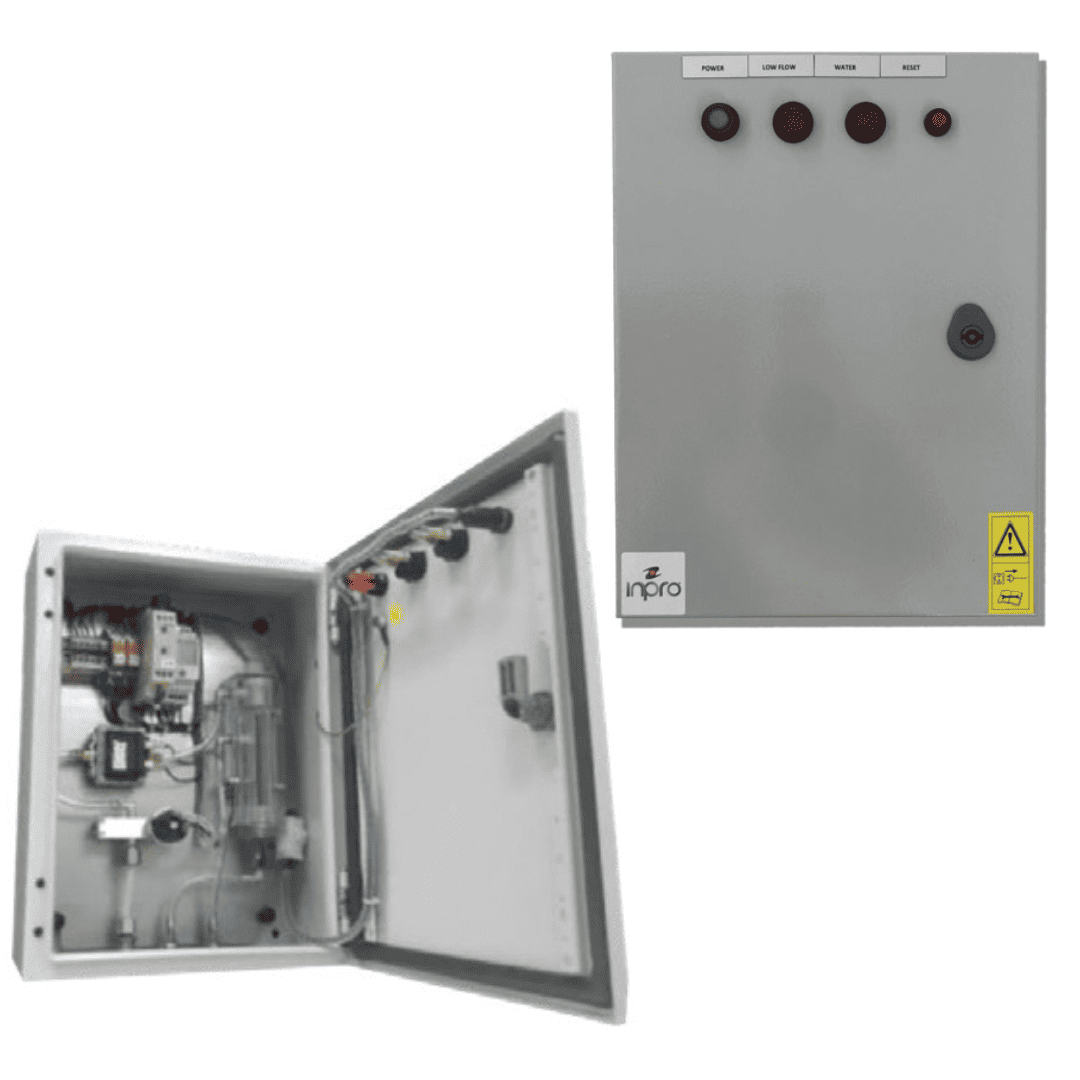

At INPRO we have several filter products and within our range of products for automatic polishing systems for the treatment of fuels, the SAFA, MiniSAFA and MicroSAFA stand out.

SAFA

For multiple and large fuel storage tanks, up to “n” main tanks. Fixed or portable execution available.

MINISAFA

For single and large fuel storage tanks, up to 50000 l. volume. Fixed or portable execution available.

MICROSAFA

For day tanks up to 2000 l.

FILTER PRODUCT OPERATION AND PROCESS VIDEOS

FILKIT- FILTER Trolley diesel and Cyclic fuel filtration

FG 100 Filter INPRO

Examples of our fuel filtering and fuel polishing equipment installed in projects:

Other articles about Polishing and Filtering Systems

Automatic fuel polishing system: SAFA, MiniSAFA and MicroSAFA

The function of a SAFA polishing system is to maintain the fuel in optimal condition in an automated way.

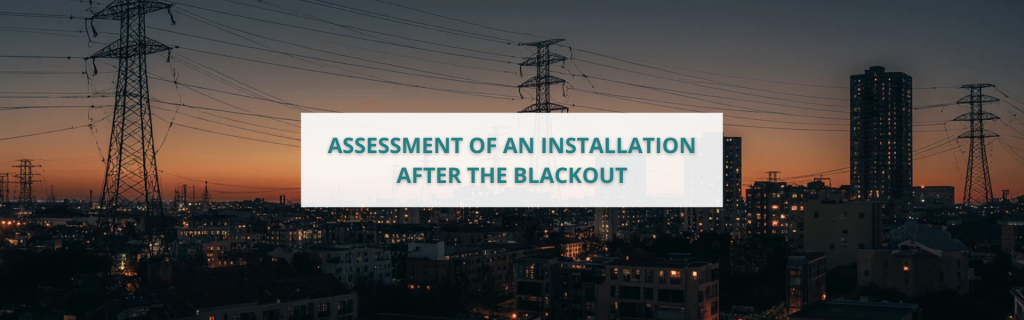

Fuel management: polishing systems prevent data centre blackouts

The real challenge does not always lie in the generators, but in an inadequate fuel management system.

Range of preventive polishing systems and FilKit Troley

We have a wide range of preventive filtering systems for fuel treatment. Our line includes the following products…

Automatic Fuel Polishing System Information

For more information about our products, services and data centre projects, please send an email to info@inprord.com or fill in the form below: