Preventive fuel polishing systems

At INPRO, we have a wide range of preventive polishing systems for fuel treatment. Our product line includes SAFA, MiniSAFA, MicroSAFA (automatic systems) and Portable MiniSAFA Filter equipment designed specifically for diesel or gas oil. This equipment separates water from the fuel and removes solid particles in suspension. In addition, through recirculation, they homogenise and oxygenate the fuel, which helps prevent the proliferation of bacteria that can affect an installation.

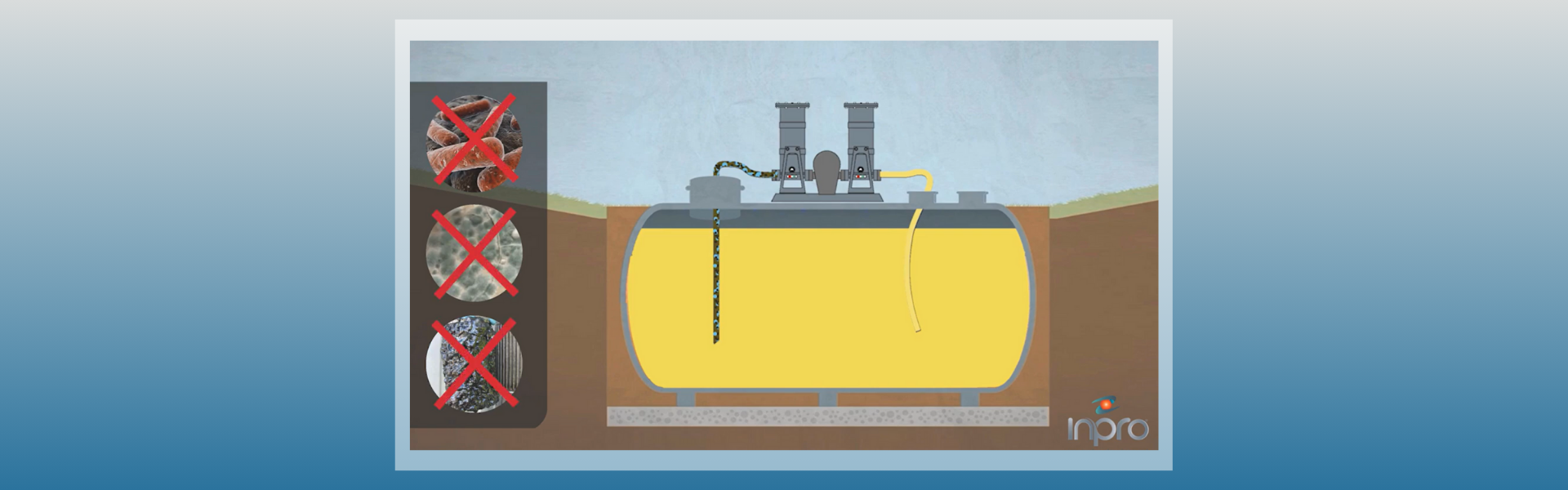

Bacteria in diesel fuel not only feed on its components, but also generate residues that can compromise both the quality and stability of the fuel and the integrity of the supply system. It is therefore essential to implement preventive measures to control bacterial growth and maintain diesel quality.

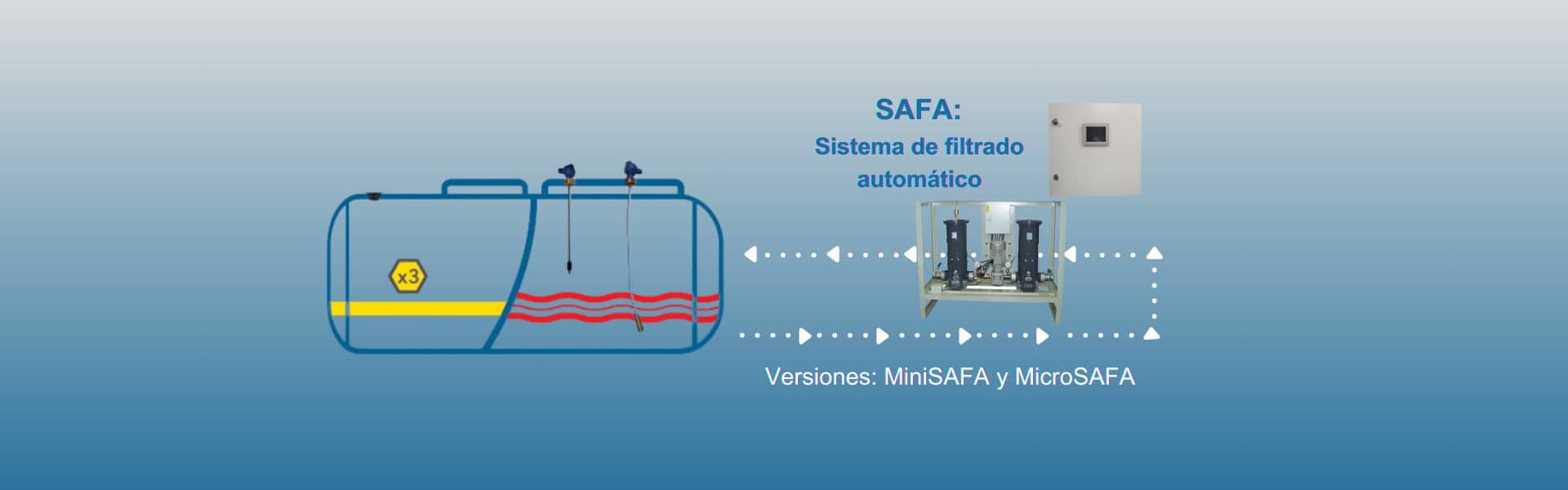

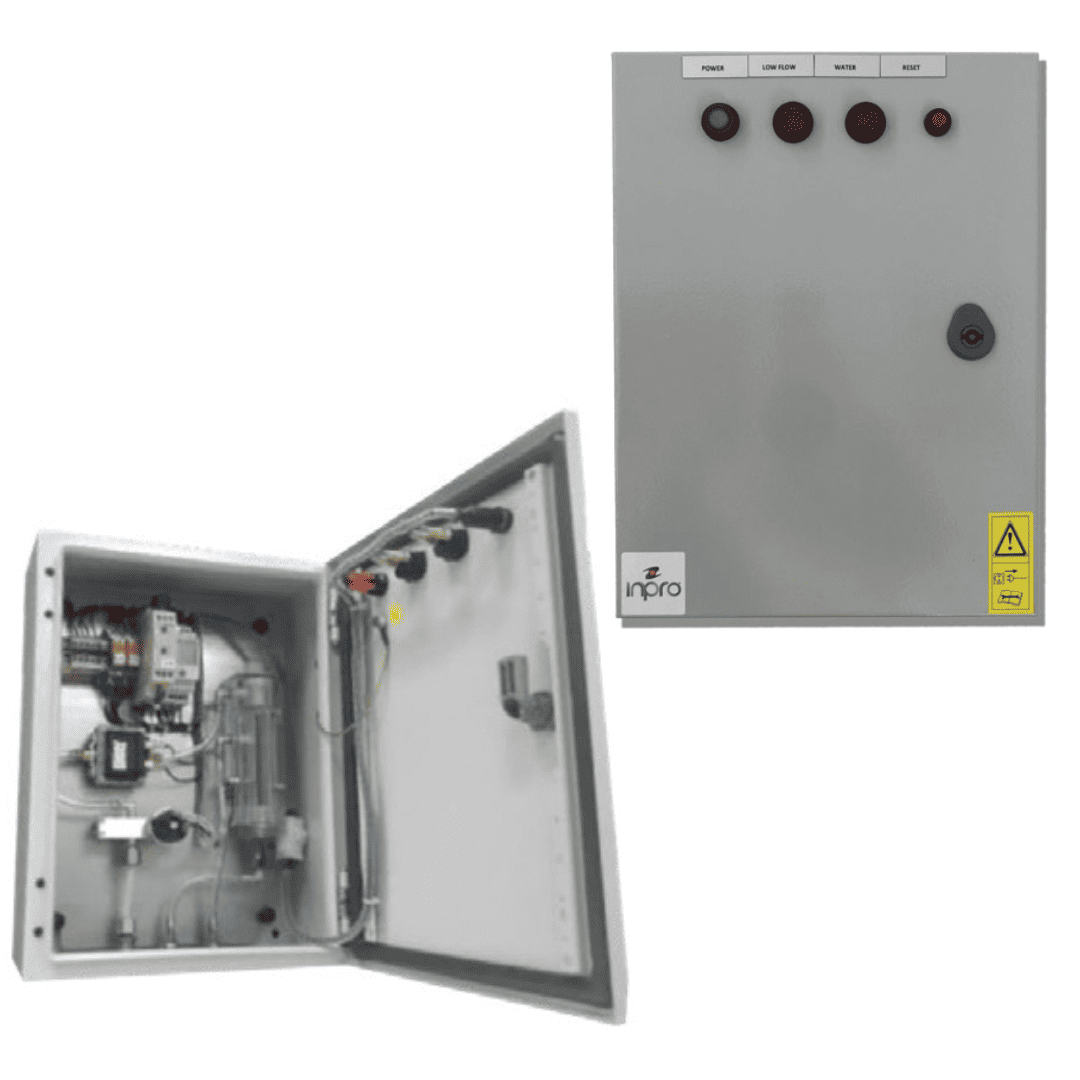

SAFA

For multiple and large fuel storage tanks, up to “n” main tanks. Fixed or portable execution available.

MINISAFA

For single and large fuel storage tanks, up to 50000 l. volume. Fixed or portable execution available.

MICROSAFA

For day tanks up to 2000 l.

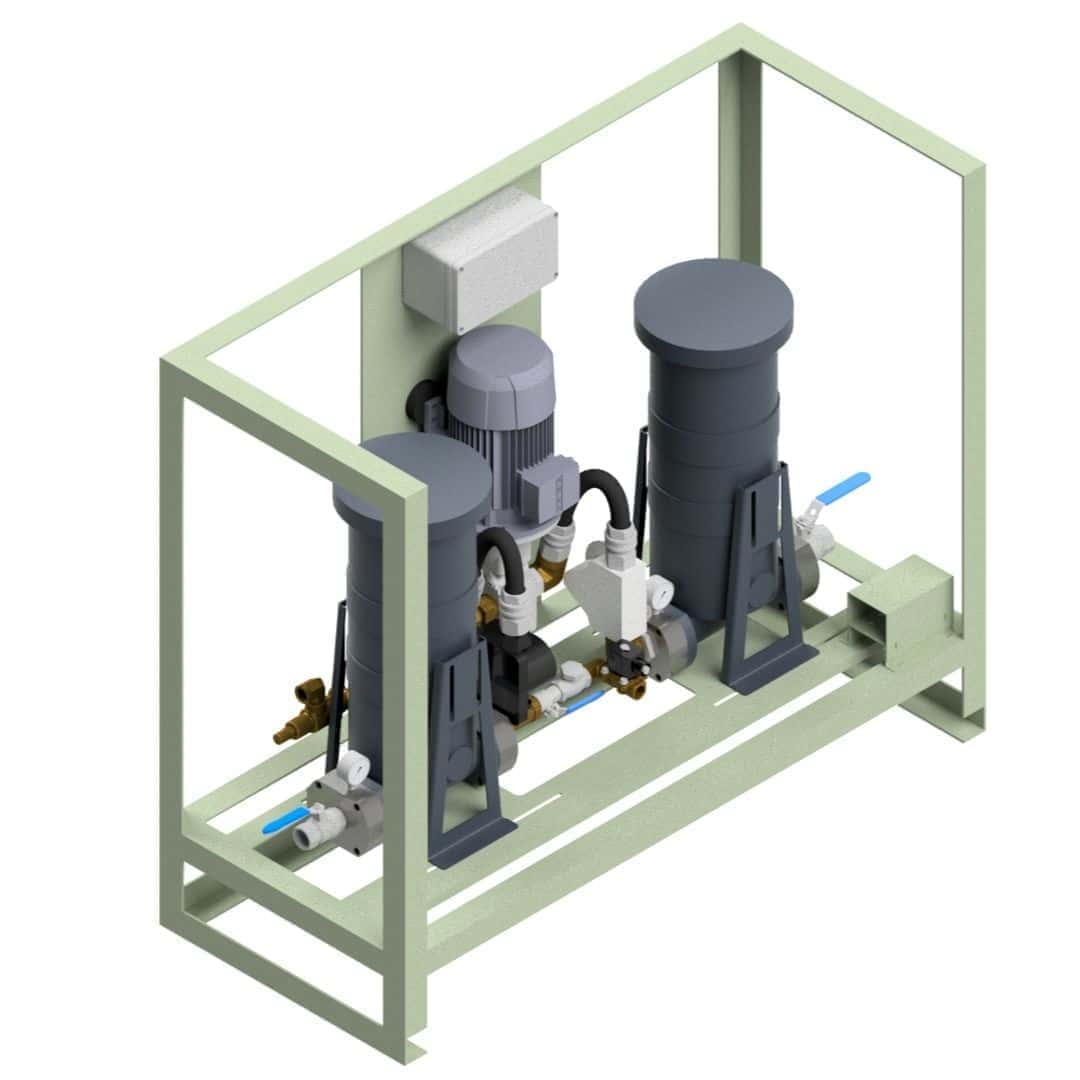

Portable MiniSAFA filter equipment

Portable MiniSAFA Filtration Equipment FG-100 x 2 + AG-46: Mobile filtration equipment 40 l/min.

Portable MiniSAFA filter equipment is designed to precisely remove dirt and rust from the fuel, enabling clean refuelling that meets customer expectations.

Filtering the fuel not only ensures quality service, but also protects the supply equipment, preventing failures, breakdowns and possible damage over time. In addition, the Filkit is compatible with a wide range of fluids, including diesel, biodiesel, petrol and other liquids, making it a versatile and effective solution for all filtering circumstances.

VIdeo: Cyclic fuel filtration- FILKIT- FILTER Trolley

Composed of:

-

Metal tube stand with handle and wheels for internal and external circulation (light and easy to handle).

-

Hose reel bracket for hose rewinding and gun hanging.

-

Self-priming pump AG-46 230 VAC.

-

Filtering in two filtering stages:

-

25 µm (micron) FG-100BIO microfilter.

-

5 µm (micron) FG-100 microfilter.

-

-

Shut-off valve at pump inlet and filter outlet.

-

Pre-filter FUP-1 at the pump inlet.

When to use a Portable MiniSAFA filter equipment?

Ideal filtering equipment for maintenance work.

This trolley filter has water absorption properties, providing a final product in optimum condition for tanks where fuel is stored for long periods of time. The Portable MiniSAFA filter is the ideal solution for maintenance work on fuel installations:

-

Designed with a wheeled trolley, the Portable MiniSAFA is a maintenance kit that allows easy movement between tanks, making cleaning and filtering effortless.

-

Its mobile structure makes it easy to move from one tank to another, optimising the time and efficiency of each intervention.

-

Thanks to its robust design and easy manoeuvrability, the Portable MiniSAFA is perfect for maintenance companies that require a reliable and versatile piece of equipment to work throughout the facility.

-

With the Portable MiniSAFA, filtering tasks can be performed quickly and without interruption, ensuring that the fuel in each tank is free of impurities and ready for use.

How to prolong the life of a tank and machinery?

By eliminating all the problems that water, bacteria and impurities cause to the engine and tanks. By installing a scrubber, the filter elements will absorb the emulsified water and filter out the micro impurities, preventing sludge and sediment from building up in the tanks. With regular microfiltration, the tank will always be clean and the fuel will always be in perfect condition.

Why preventive polishing systems are necessary in a Critical Facility?

Keeping fuel in optimal condition is essential to ensure the functionality of any critical system. A failure in fuel quality can compromise the entire system’s operability, rendering even back-up equipment useless if the fuel is contaminated and unable to perform its function.

In critical facilities such as hospitals, airports and data centres, system functionality is a safety issue; having an automated system in place to ensure optimal fuel conditions is, in many cases, a non-negotiable necessity. Internationally, few companies manufacture preventative fuel filtering systems, and INPRO is proud to offer these unique products in our catalogue.

FILTER PRODUCT OPERATION AND PROCESS VIDEOS

The importance of installing a filter

FG 100 Filter INPRO

Other articles about Polishing and Filtering Systems

Automatic fuel polishing system: SAFA, MiniSAFA and MicroSAFA

The function of a SAFA polishing system is to maintain the fuel in optimal condition in an automated way.

Fuel management: polishing systems prevent data centre blackouts

The real challenge does not always lie in the generators, but in an inadequate fuel management system.

Maximising Efficiency and Economy: The Automatic Fuel Polishing System

In applications where fuel is required, the quality of the fuel is critical to optimal performance….

Automatic Fuel Polishing System Information

For more information about our products, services and data centre projects, please send an email to info@inprord.com or fill in the form below: